F03B1 - MATERIAL GUIDES - BAMBOO SELECTION

F03B1-1 General & Technical Information

F03B1-2 Bamboo

F03B1-3 Bamboo flooring selection criteria

F03B1-4 Other considerations

F03B1-2 Bamboo

F03B1-3 Bamboo flooring selection criteria

F03B1-4 Other considerations

Preface:

This study guide covers selection requirements for bamboo flooring and related materials.

1 • GENERAL AND TECHNICAL INFORMATION

.01 Bamboo flooring manufacturers and suppliers have samples as well as technical information on their products available to the design authority. Some caution should be exercised in reviewing this material so that a manufacturer's particular bamboo flooring type can be fairly compared to the same type from another manufacturer. This involves careful scrutiny of the material specifications and test data

.02 Technical information regarding installation methods is also available from bamboo flooring manufacturers and suppliers in regard to their specific products. General information on product installation is also available to a degree, from Provincial Floor Covering Associations.

This study guide covers selection requirements for bamboo flooring and related materials.

1 • GENERAL AND TECHNICAL INFORMATION

.01 Bamboo flooring manufacturers and suppliers have samples as well as technical information on their products available to the design authority. Some caution should be exercised in reviewing this material so that a manufacturer's particular bamboo flooring type can be fairly compared to the same type from another manufacturer. This involves careful scrutiny of the material specifications and test data

.02 Technical information regarding installation methods is also available from bamboo flooring manufacturers and suppliers in regard to their specific products. General information on product installation is also available to a degree, from Provincial Floor Covering Associations.

2 • BAMBOO

Note: This unique type of flooring is usually classified as "wood" flooring.

Note: This unique type of flooring is usually classified as "wood" flooring.

.01 Bamboo is not a hardwood but a woody perennial evergreen grass from an extremely varied plant with over a hundred genera and over 1000 different species that range in size from less than a few feet to well over 100 feet in height. It is one of the most tremendous living resources in the world. Its strength and durability lend it to many uses - from use as a structural building material, a food source, and for flooring.

|

Bamboo is made of long cellulose fibres that run parallel to each other over the entire length of the stalk. These longitudinal open cells (which carry water to feed the bamboo) are encased in lingin, a substance which strongly binds the fibres together. These fibres are most densely concentrated closer to the outer protective surface of the stalk, whereas the innermost fibres are the weakest and starchiest. The nodes, which act to segment the bamboo, are the stalks' supporting discs. Although the density of the material around the nodal region is tremendous, the node is actually the weakest part of the outer plant as it breaks the continuity of the parallel fibrous strands.

|

.02 Bamboo is one of the fastest growing plants in the world. New shoots come up in the spring and can grow 600 to 900 mm (24" to 36") or more in a 24 hour period and reach full size in just a couple of months. Once a new culm (cane) reaches full size and leafs out, it increases in diameter but never grows any higher. Over a few years the bamboo forms a grove and builds up reserves over a few seasons, sending up larger and larger canes each spring. When the grove has reached a large enough size it will send up full size (giant) canes each spring. Culms may live up to ten years or more and can grow up to 300 mm (12") in diameter.

.03 Hardness: The hardness of flooring is its ability to resist indentation, wear, and marring. The hardness of bamboo flooring varies with the species, colour (natural bamboo is approximately 10% harder than carbonized bamboo), and with the grain direction of bamboo (horizontal or flat grain material is about 15% harder than vertical grain material). Even though bamboo is a grass it is as hard as some hardwood species (Refer to Janka rating table in Part D03D - Material Guide - Species (for Hardwood). Not all bamboo flooring is the same however. Some species of bamboo are harder than others. Most bamboo flooring is made from the Moso species (Phyllostachys pubescens), as it is the most abundant. Other species are also used and because of this, the relative hardness of bamboo flooring may vary slightly.

A number of other factors also affect hardness and should be understood:

The durability of bamboo flooring depends not only on its hardness but also on its initial treatment (where the starch is transformed into a dense medium), on the type of finish applied, and the amount of traffic the flooring will be subject to. Some flooring manufacturers may not treat their bamboo with the same level of "thoroughness" resulting in a significant amount of starch remaining in the flooring. This leaves the bamboo subject to attack from certain insects that may devour the floor and ultimately destroy it.

.04 Bamboo Flooring Fabrication: Bamboo canes are harvested (cut down) after they mature and harden (in about four years) and are set out to dry in the sun. The canes are then cut into thin uniform strips that are then shaped and planed on all sides. This is the basic building block that most bamboo flooring is made from. In addition, waste from this fabricating process along with strands of bamboo is laminated under pressure to produce "oriented" bamboo strand flooring.

There are also manufacturing differences in the planks, which differ mainly in thickness, width, and length. As a new hard-surface flooring product the long-term performance of bamboo flooring is still being evaluated.

3 • BAMBOO FLOORING SELECTION CRITERIA

.01 Individuals may choose bamboo flooring because it is a natural (green and sustainable) material, for its unique / distinctive appearance and pattern, and/or for its durability (bamboo flooring has hardness approximating Maple and stability exceeding Oak). Bamboo flooring also resists moisture better than virtually all hardwood flooring species.

.02 Bamboo flooring must not only be aesthetically pleasing to the Owner (the end user) and the designer but must also retain an attractive appearance throughout its life expectancy. Paying careful attention to flooring selection criteria and the following criteria will ensure an installation meeting the requirements for a durable and visually appearing floor.

.03 Many factors enter into choosing bamboo flooring to meet a project's requirements. In addition to general flooring selection criteria indicated in Part A17 there are a number of things that should be considered when choosing bamboo flooring:

.03 Hardness: The hardness of flooring is its ability to resist indentation, wear, and marring. The hardness of bamboo flooring varies with the species, colour (natural bamboo is approximately 10% harder than carbonized bamboo), and with the grain direction of bamboo (horizontal or flat grain material is about 15% harder than vertical grain material). Even though bamboo is a grass it is as hard as some hardwood species (Refer to Janka rating table in Part D03D - Material Guide - Species (for Hardwood). Not all bamboo flooring is the same however. Some species of bamboo are harder than others. Most bamboo flooring is made from the Moso species (Phyllostachys pubescens), as it is the most abundant. Other species are also used and because of this, the relative hardness of bamboo flooring may vary slightly.

A number of other factors also affect hardness and should be understood:

- Bamboo grows from the ground to as tall as 40 to 50 feet within 3 to 6 months and then stops growing. As it still needs about 5 years to grow internally for maturity, bamboo that is harvested in the 3rd or 4th year is not recommended for flooring.

- China has about 8 provinces that grow bamboo with each province having their own controlling policies some of which permit random cutting of bamboo no matter how young it is. Buyers need to clearly understand this, as some bamboo flooring will be made using mixed-age bamboo.

- Bamboo contains high protein and sugar. Because of this, bamboo will easily develop mould if it is not treated in a timely manner (particularly if it is in a hot and humid climate). Once mould develops, it can never be removed, and bamboo flooring made from this bamboo will always look dull or lifeless. All bamboo to be used for bamboo flooring should ideally be treated within 3 days and no later than 5 days from the time it is cut and delivered to the factory.

The durability of bamboo flooring depends not only on its hardness but also on its initial treatment (where the starch is transformed into a dense medium), on the type of finish applied, and the amount of traffic the flooring will be subject to. Some flooring manufacturers may not treat their bamboo with the same level of "thoroughness" resulting in a significant amount of starch remaining in the flooring. This leaves the bamboo subject to attack from certain insects that may devour the floor and ultimately destroy it.

.04 Bamboo Flooring Fabrication: Bamboo canes are harvested (cut down) after they mature and harden (in about four years) and are set out to dry in the sun. The canes are then cut into thin uniform strips that are then shaped and planed on all sides. This is the basic building block that most bamboo flooring is made from. In addition, waste from this fabricating process along with strands of bamboo is laminated under pressure to produce "oriented" bamboo strand flooring.

There are also manufacturing differences in the planks, which differ mainly in thickness, width, and length. As a new hard-surface flooring product the long-term performance of bamboo flooring is still being evaluated.

3 • BAMBOO FLOORING SELECTION CRITERIA

.01 Individuals may choose bamboo flooring because it is a natural (green and sustainable) material, for its unique / distinctive appearance and pattern, and/or for its durability (bamboo flooring has hardness approximating Maple and stability exceeding Oak). Bamboo flooring also resists moisture better than virtually all hardwood flooring species.

.02 Bamboo flooring must not only be aesthetically pleasing to the Owner (the end user) and the designer but must also retain an attractive appearance throughout its life expectancy. Paying careful attention to flooring selection criteria and the following criteria will ensure an installation meeting the requirements for a durable and visually appearing floor.

.03 Many factors enter into choosing bamboo flooring to meet a project's requirements. In addition to general flooring selection criteria indicated in Part A17 there are a number of things that should be considered when choosing bamboo flooring:

- Cost and Quality: In choosing bamboo flooring there is a variety of choices and therefore cost variations to choose from.

- The cost of bamboo flooring is based on a number of factors that include the type of flooring (tile, plank, or parquet), installation method (glue-down, mechanically fastened, or floating), and finish (site or pre-finished).

- The amount budgeted for bamboo flooring may limit the range of choices available. It is up to the Owner or designer to select an appropriate bamboo flooring system (material, finish, and assembly) based on a fair and equitable evaluation of materials meeting the requirements. It is very important to be well informed and to compare "apples to apples."

- Purchasing bamboo flooring at special, reduced, or give-away prices often results in consumer / user dissatisfaction. Quality bamboo flooring and installation can never be obtained at the lowest price. Consumers / Owners should not attempt to "save" on long-term appearance and performance or on the method of installation when they know they will be looking at the workmanship over the life of the flooring!

- Style and Size: Since the use of bamboo flooring in any area can have a major effect on the overall appearance the following should be considered when appropriate:

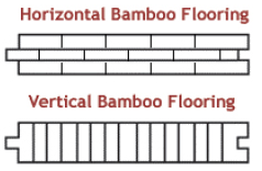

- Style: vertical or horizontal bamboo in tile, plank, or parquet style.

- Flooring unit size: width and length of plank or size of tile.

- Edge treatment: Square / smooth or modified eased edge (created by lightly sanding plank edges to remove the sharp corners). Edge treatments available must be verified with each flooring manufacturer.

- Appearance: Bamboo flooring is available in two forms (tile and plank) and types (horizontal or vertical grain and strand) and may be installed in a number of ways. It is therefore important to view full size samples of the form and type selected.

- Colour and Finish: Bamboo is available in three "colours": natural (blond), carbonized (amber), or stained (manufacturer or custom stain) with a factory or site applied matte, semi-gloss, or gloss finish.

- The selection of a bamboo flooring colour and finish should be made from actual large-scale samples of the flooring tiles or planks from the full colour range available and not from a small sample or from photographs. In addition any colour variations that may occur within the selected type should be thoroughly discussed and if necessary samples showing expected variations should be viewed

- The choice of a colour and finish is a very subjective matter and one of personal choice. As one of the two main decorative elements within a space (the other being walls) the choice of colour and finish becomes very important in setting the "tone" and in contributing to the ambiance of the space that it is in. A colour / finish can be a low-gloss light natural one or it can be a dark high-gloss dark one that becomes the focal point of the area or room and one that makes a statement.

- As a natural material, bamboo is sensitive to light and/or oxygen, and over time, will change colour. Bamboo flooring must be finished not only to protect it but also to maintain a consistent colour.

- Bamboo flooring may be site finished after installation or be pre-finished at the place of manufacture. Each finish has it advantages and disadvantages and an impact on cost.

- A variety of finish options such as the type of material (natural or carbonized), stains, finishes, and gloss levels are available. Once selected, actual material samples with the selected finish applied should be provided for review of the final overall appearance.

- It may be best to view a large number of actual pieces or an actual installation of the selected material with the selected finish. In addition, it is also important to determine what the selected material will look like if it is pre-finished or if it is to be site finished and what it will look like after it has "aged" in place.

- Finally, it is also important to review what the finish and gloss level will look like under actual artificial and natural lighting conditions and what it will look like when exposed to direct sunlight and UV rays. The latter should be conducted using a finished sample that is "partly" exposed to sunlight for a few days. The unexposed part will indicate the short-term effects of sun and UV rays on the finish.

- Installation Method and Arrangement:

- Bamboo flooring (usually tile and parquet flooring) may be glued to an acceptable substrate, may be mechanically fastened (plank flooring), or may be installed as a loose-laid or floating (plank flooring).

- Bamboo flooring may be installed in a variety of ways. These range from planks installed in a parallel or diagonal fashion, and tiles installed in a chequer board or in an offset pattern, etc. The arrangement and direction of installation will have an impact on cost.

- Underlayment: - materials for acoustical / insulation purposes.

- Additional Materials and Accessories: base boards, edge trims, etc.

- Performance and Appearance Retention: Location and usage.

4 • OTHER CONSIDERATIONS

.01 Acoustical Issues: Because of the hard surface of bamboo flooring, the generation of airborne and impact noise can become an issue within and between adjoining spaces. Where this is a concern, the use of an acoustical underlayment / separation layer between the bamboo flooring and substrate surface to reduce such noise must be considered.

Installing bamboo flooring over an "acoustical" underlayment may provide an adequate noise reduction coefficient. In all cases however, the acoustical ratings specified by underlayment manufacturers must be verified.

For an explanation of acoustical testing and requirements refer to A08C - Acoustical Issues.

.02 Radiant Heating: While radiant floor heating will not harm bamboo flooring, variances in moisture content may cause it to shrink or expand. Adding heat to the floor assembly makes attention to moisture even more critical. The installation of bamboo flooring over radiant heated substrates is subject to the flooring manufacturer's recommendations.

As a general rule most bamboo flooring manufacturers allow bamboo flooring to be installed over radiant heated floors. This must however be verified with each flooring manufacturer.

.03 Guarantee / Warranties offered.

.04 Specifications Requirements:

.05 Caveat Emptor (Buyer Beware):

.01 Acoustical Issues: Because of the hard surface of bamboo flooring, the generation of airborne and impact noise can become an issue within and between adjoining spaces. Where this is a concern, the use of an acoustical underlayment / separation layer between the bamboo flooring and substrate surface to reduce such noise must be considered.

Installing bamboo flooring over an "acoustical" underlayment may provide an adequate noise reduction coefficient. In all cases however, the acoustical ratings specified by underlayment manufacturers must be verified.

For an explanation of acoustical testing and requirements refer to A08C - Acoustical Issues.

.02 Radiant Heating: While radiant floor heating will not harm bamboo flooring, variances in moisture content may cause it to shrink or expand. Adding heat to the floor assembly makes attention to moisture even more critical. The installation of bamboo flooring over radiant heated substrates is subject to the flooring manufacturer's recommendations.

As a general rule most bamboo flooring manufacturers allow bamboo flooring to be installed over radiant heated floors. This must however be verified with each flooring manufacturer.

.03 Guarantee / Warranties offered.

- For and explanation of warranties and guarantees refer to Part Part A06 – Guarantees and Warranties.

- A number of issues in regard to the repair and/or replacement of bamboo flooring under warranty need to be clarified. These include:

- Will there be charges for furniture removal, etc.?

- Will there be charges for the cost of removal of existing and supply and installation of new flooring and related materials?

- Will there be charges for re-finishing?

- If the existing bamboo flooring is no longer available, what is provided for under the policy?

- Is the replacement or any other claim pro-rated?

- Guarantee and warranty claims will require examination by the bamboo flooring contractor / supplier and/or a representative of the manufacturer, and if deemed necessary, by an independent third party inspection service (e.g. NFCA Quality Assurance Program Inspector). Usually proof of purchase must accompany any claim.

.04 Specifications Requirements:

- For and explanation of warranties and guarantees refer to Part A06 – Guarantees and Warranties.

- Specifying bamboo flooring informs the manufacturer / supplier in exact terms of what species, grade, type of flooring material, and finish is required. Due diligence and a correct and clearly written specification is a necessity to obtain the required results. This should be done by a design professional who clearly understands the specification writing process and requirements using the correct format and content. How is this done?

- Having examined the substrate conditions and the sort of traffic to which the area under consideration will be subjected to and having selected the material and finish, the next step is to precisely define these elements. These choices must be made to provide optimum performance and durability as well as the desired aesthetics within the budget available. They should also be carefully discussed with and examined by bamboo flooring manufacturer representatives while discussing the project with the architect and/or designer, the specifier, and the contractor where applicable.

- To write a correct bamboo flooring specification also requires knowledge of basic construction and how various elements, such as concrete substrates, will influence the bamboo flooring's final performance. The specifier must also be aware of established Code and industry standards, and where applicable, incorporate these within the specification as well. The specification should also be written in such a manner that it allows for the consideration of products from competing manufacturers that conform to the specification requirements.

.05 Caveat Emptor (Buyer Beware):

- To alleviate problems resulting from the improper selection and/or installation of bamboo flooring, it is the Consumer's responsibility to be properly informed. Both the design professional and the bamboo flooring dealer also have an obligation to inform the consumer of the pertinent facts in choosing an appropriate bamboo flooring system.

- One way to be assured of receiving quality floor coverings and a professional installation is to deal with reputable and knowledgeable firms who will charge a fair and reasonable price for all materials and installation services. Firms that are proud to provide a quality installation are aware that by doing so they have created one more satisfied customer who will return to purchase again or one who will recommend them to others.