CC6 - EVALUATION AND TESTING PROCEDURES - AATCC

Preface:

The following list of evaluation and testing procedures for carpet from the American Association of Textile Chemists and Colourists (AATCC) is provided for general information only. The list is not comprehensive and specifiers and other persons using it are advised to consult with AATCC as to applicable procedures as well as with the appropriate carpet manufacturer as to what specific procedure is applicable.

Procedures indicated below are not dated as such dates change on a random basis due to periodic review and revisions. It is up to the reader / design authority to verify if the procedure still exists and what the current date of the procedure is with AATCC. Refer to Part C02 – Reference Associations for contact information.

AATC EVALUATION PROCEDURES

AATCC Evaluation Procedure 1, Gray Scale for Colour Change

This evaluation procedure describes the use of a Gray Scale for visually evaluating changes in colour of textiles resulting from colourfastness tests. For instrumental assessment of change of colour of a test specimen refer to AATCC Evaluation Procedure 7. A precise colourimetric specification of the differences between the reference and the 9-Step scale is given as a permanent record against which newly prepared Gray Scales, and old scales that might have changed, can be compared.

AATCC Evaluation Procedure 2, Gray Scale for Staining

This evaluation procedure describes the use of the Gray Scale for evaluating staining of unstained textiles resulting from colourfastness tests. A precise colourimetric specification of the differences between the reference and the 9-Step Scale is given as a permanent record against which newly prepared Gray Scales, and old Scales that may have been changed, can be compared.

AATCC Evaluation Procedure 7, Instrumental Assessment of the Change in Colour of a Test Specimen

This evaluation procedure is intended as an alternative to the visual method of Evaluation Procedure 1, Gray Scale for Colour Change, for assessing the change in colour of a test specimen. It is applicable to any test method referring to Gray Scales except those which involve treatment with solutions containing fluorescent whitening agents (FWA).

AATCC TEST PROCEDURES

AATCC 6, Colourfastness to Acids and Alkalis

Test specimens are evaluated for resistance to simulated action of acid fumes, sizes, alkaline sizes, alkaline cleansing agents, and alkaline street dirt. These test methods are applicable to textiles made from all fibres in the form of yarns or fabrics, whether dyed, printed, or otherwise coloured.

The specimens are steeped in or spotted with the required solutions by means of simple laboratory equipment, and are then examined for changes in colour.

AATCC 8, Colourfastness to Crocking: AATCC Crockmeter Method

This test method is designed to determine the amount of colour transferred from the surface of coloured textile materials to other surfaces by rubbing. It is applicable to textiles made from all fibres in the form of yarn or fabric whether dyed, printed, or otherwise coloured.

Test procedures employing white test cloth squares, both dry and wet with water, are given. As washing, dry cleaning, shrinkage, ironing, finishing, etc., may affect the degree of colour transfer from a material, the test may be made before, after, or before and after such treatment.

A coloured test specimen is rubbed with a white crock test cloth under controlled conditions. Colour transferred to the white test cloth is assessed by a comparison with the Gray Scale for Staining or the Chromatic Transference Scale and a grade is assigned.

AATCC 16, Colourfastness to Light

This test method provides the general principles and procedures that are currently in use for determining the colourfastness to light of textile materials. The test options described are applicable to textile materials of all kinds and for colourants, finishes, and treatments applied to textile materials.

Test Options included are:

Samples of the textile material to be tested and the agreed upon comparison standard(s) are exposed simultaneously to a light source under specified conditions. The colourfastness to light of the specimen is evaluated by comparison of the colour change of the exposed portion to the masked control portion of the test specimen or unexposed original material, using the AATCC Gray Scale for Colour Change or by instrumental colour measurement. Lightfastness classification is accomplished by evaluation versus a simultaneously exposed series of AATCC Blue Wool Lightfastness Standards.

AATCC 20, Fibre Analysis: Qualitative

This test method describes the physical, chemical, and microscopical techniques for identifying textile fibres used commercially in the United States. Fibres may be examined in raw fibre form or taken from yarn or fabric.

These test methods may be used to identify generic fibre types as defined by the Textile Fibres Products Identification Act and subsequent rules and regulations of the Federal Trade Commission. Quantitative methods for determining percentages in blends of fibres are covered by AATCC Test Method 20A, Fibre Analysis: Quantitative.

AATCC 20A, Fibre Analysis: Quantitative

This method presents individual procedures for the quantitative determination of moisture content, non-fibrous content and fibre composition of textiles.

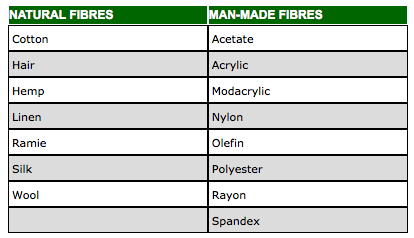

The procedures for the determination of fibre composition include mechanical, chemical, and microscopical methods. They are applicable to blends of the following generic classes:

The following list of evaluation and testing procedures for carpet from the American Association of Textile Chemists and Colourists (AATCC) is provided for general information only. The list is not comprehensive and specifiers and other persons using it are advised to consult with AATCC as to applicable procedures as well as with the appropriate carpet manufacturer as to what specific procedure is applicable.

Procedures indicated below are not dated as such dates change on a random basis due to periodic review and revisions. It is up to the reader / design authority to verify if the procedure still exists and what the current date of the procedure is with AATCC. Refer to Part C02 – Reference Associations for contact information.

AATC EVALUATION PROCEDURES

AATCC Evaluation Procedure 1, Gray Scale for Colour Change

This evaluation procedure describes the use of a Gray Scale for visually evaluating changes in colour of textiles resulting from colourfastness tests. For instrumental assessment of change of colour of a test specimen refer to AATCC Evaluation Procedure 7. A precise colourimetric specification of the differences between the reference and the 9-Step scale is given as a permanent record against which newly prepared Gray Scales, and old scales that might have changed, can be compared.

AATCC Evaluation Procedure 2, Gray Scale for Staining

This evaluation procedure describes the use of the Gray Scale for evaluating staining of unstained textiles resulting from colourfastness tests. A precise colourimetric specification of the differences between the reference and the 9-Step Scale is given as a permanent record against which newly prepared Gray Scales, and old Scales that may have been changed, can be compared.

AATCC Evaluation Procedure 7, Instrumental Assessment of the Change in Colour of a Test Specimen

This evaluation procedure is intended as an alternative to the visual method of Evaluation Procedure 1, Gray Scale for Colour Change, for assessing the change in colour of a test specimen. It is applicable to any test method referring to Gray Scales except those which involve treatment with solutions containing fluorescent whitening agents (FWA).

AATCC TEST PROCEDURES

AATCC 6, Colourfastness to Acids and Alkalis

Test specimens are evaluated for resistance to simulated action of acid fumes, sizes, alkaline sizes, alkaline cleansing agents, and alkaline street dirt. These test methods are applicable to textiles made from all fibres in the form of yarns or fabrics, whether dyed, printed, or otherwise coloured.

The specimens are steeped in or spotted with the required solutions by means of simple laboratory equipment, and are then examined for changes in colour.

AATCC 8, Colourfastness to Crocking: AATCC Crockmeter Method

This test method is designed to determine the amount of colour transferred from the surface of coloured textile materials to other surfaces by rubbing. It is applicable to textiles made from all fibres in the form of yarn or fabric whether dyed, printed, or otherwise coloured.

Test procedures employing white test cloth squares, both dry and wet with water, are given. As washing, dry cleaning, shrinkage, ironing, finishing, etc., may affect the degree of colour transfer from a material, the test may be made before, after, or before and after such treatment.

A coloured test specimen is rubbed with a white crock test cloth under controlled conditions. Colour transferred to the white test cloth is assessed by a comparison with the Gray Scale for Staining or the Chromatic Transference Scale and a grade is assigned.

AATCC 16, Colourfastness to Light

This test method provides the general principles and procedures that are currently in use for determining the colourfastness to light of textile materials. The test options described are applicable to textile materials of all kinds and for colourants, finishes, and treatments applied to textile materials.

Test Options included are:

- Carbon-Arc Lamp, Continuous Light

- Sunlight (Discontinued; see 32.1)

- Daylight

- Carbon-Arc Lamp, Alternate Light and Dark

- Water-Cooled Xenon-Arc Lamp, Continuous Light

- Water-Cooled Xenon-Arc Lamp, Alternate Light and Dark

- Fastness Above L-7 (Discontinued; see 32.2)

- Air-Cooled Xenon Arc-Lamp, Continuous Light

- Air-Cooled Xenon Arc-Lamp, Continuous Light

- Air-Cooled Xenon Arc-Lamp, Alternate Light and Dark.

Samples of the textile material to be tested and the agreed upon comparison standard(s) are exposed simultaneously to a light source under specified conditions. The colourfastness to light of the specimen is evaluated by comparison of the colour change of the exposed portion to the masked control portion of the test specimen or unexposed original material, using the AATCC Gray Scale for Colour Change or by instrumental colour measurement. Lightfastness classification is accomplished by evaluation versus a simultaneously exposed series of AATCC Blue Wool Lightfastness Standards.

AATCC 20, Fibre Analysis: Qualitative

This test method describes the physical, chemical, and microscopical techniques for identifying textile fibres used commercially in the United States. Fibres may be examined in raw fibre form or taken from yarn or fabric.

These test methods may be used to identify generic fibre types as defined by the Textile Fibres Products Identification Act and subsequent rules and regulations of the Federal Trade Commission. Quantitative methods for determining percentages in blends of fibres are covered by AATCC Test Method 20A, Fibre Analysis: Quantitative.

AATCC 20A, Fibre Analysis: Quantitative

This method presents individual procedures for the quantitative determination of moisture content, non-fibrous content and fibre composition of textiles.

The procedures for the determination of fibre composition include mechanical, chemical, and microscopical methods. They are applicable to blends of the following generic classes:

AATCC 93, Abrasion Resistance of Fabrics: Accelerotor Method

This test method is intended for evaluating the resistance of fabrics and other flexible materials to abrasion.

An unfettered fabric specimen is driven by an impeller (rotor) along a zigzag course in a generally circular orbit within a cylindrical chamber, so that it repeatedly impinges on the walls and abradant liner of the chamber while at the same time being continually subjected to extremely rapid, high velocity impacts. The specimen is subjected to flexing, rubbing, shock, compression, stretching, and other mechanical forces during the test. Abrasion is produced throughout the specimen by rubbing of yarn against yarn, fibre against fibre, surface against surface and surface against abradant.

AATCC 94, Finishes in Textiles: Identification

This test method gives guidelines for qualitative identification of various finish components present on textile fabrics, yarns or fibres.

The identification scheme may involve any or all of the following approaches:

This test method provides a quantitative procedure for the evaluation of the degree of antibacterial activity. Assessment of antibacterial activity finishes on textile material is determined by the degree of antibacterial activity intended in the use of such materials. If only bacteriostatic activity (inhibition of multiplication) is intended, a qualitative procedure that clearly demonstrates antibacterial activity as contrasted with lack of such activity by an untreated specimen may be acceptable. However, if bactericidal activity is intended or implied, quantitative evaluation is necessary. Quantitative evaluation also provides a clearer picture for possible uses of such treated textile materials.

AATCC 109, Colourfastness to Ozone in the Atmosphere Under Low Humidities

This test method is intended for determining the resistance of the colour of textiles to the action of ozone in the atmosphere at room temperatures with relative humidities not exceeding 67%.

A test specimen and a control specimen are simultaneously exposed to ozone in an atmosphere under ambient temperatures (64-82°F) and relative humidities not exceeding 67%, until the control specimen shows a colour change corresponding to that of a standard of fading. This exposure period constitutes one cycle. The cycle is repeated (1) until the specimen shows a definite colour change or (2) for a prescribed number of cycles.

AATCC 116, Colourfastness to Crocking: Rotary Vertical Crockmeter Method

This test method is used to determine the amount of colour transferred from the surface of coloured textile materials to other surfaces by rubbing. It is applicable to textiles made from all fibres in the form of yarn or fabric, whether dyed, printed, or otherwise coloured and especially to prints where the singling out of areas smaller than possible to test with the standard AATCC Crockmeter (AATCC Test Method 8) is required.

Test procedures employing test squares either dry or wet with water or other liquids are within the scope of this method.

A test specimen held at the base of the Rotary Vertical Crockmeter is rubbed with standard test squares under controlled conditions. Colour transferred to the test squares is assessed by comparison with the Gray Scale for Staining or AATCC Chromatic Transference Scale.

AATCC-118, Oil Repellency: Hydrocarbon Resistance Test

This test method is used to detect the presence of a fluorochemical finish, or other compounds capable of imparting a low energy surface, on all types of fabrics, by evaluating the fabric's resistance to wetting by a selected series of liquid hydrocarbons of different surface tensions.

Drops of standard test liquids, consisting of a selected series of hydrocarbons with varying surface tensions, are placed on the fabric surface and observed for wetting, wicking, and contact angle. The oil repellency grade is the highest numbered test liquid which does not wet the fabric surface.

AATCC 121, Carpet Soiling: Visual Rating Method

This test method covers the measurement of the degree of cleanness of pile floor coverings, in the range from clean to a middle degree of soiling. It can be used to measure the accumulation of soil, or the removal of soil by a cleaning procedure. It can be used with pile floor coverings of any colour, pattern, structure, or fibre content.

This test method does not evaluate structural appearance changes.

The degree of difference in cleanness between an original or clean area, and the area under examination is determined by visual matching with a stepwise series of differences in grey chips selected to form a geometrical scale of differences on the dark-light axis.

AATCC 122, Carpet Soiling: Service Soiling Method

This test method evaluates the service soiling of carpets and rugs.

Specimen of carpets and selected control samples are exposed to normal foot traffic in a controlled test area. The test specimens and controls are removed and visually rated at predetermined intervals corresponding to different degrees of soiling or exposure to soiling.

AATCC 123, Carpet Soiling: Accelerated Soiling Method

This test method describes a procedure for the accelerated soiling of carpets. It can be used to compare the soiling propensity of two or more carpets; or it can be used to soil carpets as a preliminary step in measuring either the ability of a carpet to be cleaned or the efficiency of a cleaning process. This accelerated carpet soiling method has been found to give similar results to floor service soiling, but its use is recommended only as a screening method and not as a replacement for floor testing.

Specimens of carpet are tumbled together with prepared synthetic soil in a laboratory ball mill for a predetermined time.

AATCC 129, Colourfastness to Ozone in the Atmosphere under High Humidities

This test method is used for determining the resistance of the colour of textiles to the action of ozone in the atmosphere at elevated temperatures with relative humidities above 85%.

A test specimen and a swatch of control sample are simultaneously exposed to ozone in an atmosphere which is maintained at 87.5 ± 2.5% relative humidity and a temperature of 40 ± 1 C (104 ± 2 F) until the control sample shows a colour change corresponding to that of a standard of fading. The cycles are repeated until the specimen shows a definite colour change or for a prescribed number of cycles.

On certain fibres, dye fading does not readily take place at humidities below 85%. Testing at high humidities is required to produce colour change that predicts service fading under warm, humid conditions.

AATCC 134, Electrostatic Propensity of Carpets

This test method assesses the static-generating propensity of carpets developed when a person walks across them by using a controlled laboratory simulation of conditions that may be encountered in practice. The simulation is focused on the use of those conditions known from experience to be strong contributors to excessive accumulation of static charges.

This test method does not include standards of performance. The specification requirements pertinent to any given application can vary considerably, depending on the specific demands of the application.

AATCC 138, Cleaning: Washing of Textile Floor Coverings

This test method is a laboratory procedure designed to simulate changes that occur in washing of a textile floor covering during cleaning.

This method is recommended only for small specimens with dimensions not exceeding the capacity of commercially available laboratory equipment.

This test method may be used on soiled, as well as unsoiled, textile floor coverings.

This wet cleaning procedure can be used for the evaluation of:

AATCC 165, Colourfastness to Crocking: Textile Floor Coverings - AATCC Crockmeter Method

This test method is designed to determine the degree of colour transfer from the surface of textile floor coverings to other surfaces by rubbing. The intent is to reproduce as nearly as possible true-to-life situations in all constructions whether dyed, printed or otherwise coloured.

Test procedures employing white test cloths, both dry and wet with water, are given. As the use surface of a textile floor covering may be exposed to various conditions in true-to-life situations, such as anti-soils, anti-stats, anti-microbials, etc., the test may be made before, after or before and after such situations.

AATCC 171, Carpets: Cleaning of; Hot Water Extraction Method

This test method provides a laboratory procedure to clean textile floor coverings by a technique simulating cleaning of installed floor coverings by hot water extraction, sometimes erroneously called "steam cleaning."

This test method may be used to clean a carpet in a manner that duplicates the most popular (70%) means of actual on-floor cleaning of carpets.

This test method prepares specimens that can be tested for many properties; e.g., colourfastness, dimensional stability, permanency of finishes, ease of cleaning, etc.

AATCC 174, Antimicrobial Activity Assessment of Carpets

This test method is designed to determine the antimicrobial activity of new carpet materials and consists of three procedures:

AATCC 175, Stain Resistance: Pile Floor Coverings

This test method is intended for use on pile floor coverings to determine the resistance to staining by acid food colours.

A specimen of pile floor covering is stained with a small volume of a diluted aqueous solution of Food Drug and Cosmetic (FD&C) Red 40 adjusted to an acid pH. After allowing the stained specimen to remain at controlled conditions for 24 ± 4 h, it is rinsed in water to remove all unused FD&C Red 40 dye. Any residual stain is assessed after drying.

AATCC 177, Colourfastness to Light at Elevated Temperature and Humidity: Xenon Lamp Apparatus

This test method provides the general principles and procedures which are currently in use for determining the colourfastness to light of textile materials that are used in extreme conditions of light, elevated temperature and humidity, such as trim material in automotive interiors. The test method described is applicable to materials of all kinds including applied colourants, finishes, and treatments.

The use of this test method does not imply, expressly or otherwise, an accelerated test for a specific application but does assist the user to predict performance of materials used in applications such as the interior of automobiles. The degree of correlation between any light-fastness test and the actual exposure in use must be determined mathematically and agreed upon by the contractual parties.

A specimen of the material to be tested and the agreed upon comparison standard(s) are exposed simultaneously to a light source under specified conditions. The colourfastness to light of the specimen is evaluated by determining the colour change of the exposed portion as measured before and after exposure of the test specimen, using the AATCC Gray Scale for Colour Change or by instrumental colour measurement.

AATCC 180, Colourfastness to Light at High Temperatures: Daylight Temperature Controlled Apparatus

This test method specifies the operating procedures for the exposure of automotive interior trim materials in an outdoor behind-glass apparatus in which the temperature is controlled for part of the day.

Specimen preparation, test durations, and performance evaluation procedures are covered in material specifications of the different automotive manufacturers.

Samples of the textile material to be tested and the agreed upon comparison standard(s) are exposed simultaneously under specified conditions designed to accelerate the amount of irradiance imposed upon the specimens. The amount of exposure is determined with respect to a specified degree of colour change, or alternately to a specific amount of radiant energy. The colourfastness of the specimen is evaluated by comparison of the colour change of the exposed portion of the test specimen or the unexposed original material, using the AATCC Gray Scale for Colour Change or by instrumental colour measurement.

This test method is intended for evaluating the resistance of fabrics and other flexible materials to abrasion.

An unfettered fabric specimen is driven by an impeller (rotor) along a zigzag course in a generally circular orbit within a cylindrical chamber, so that it repeatedly impinges on the walls and abradant liner of the chamber while at the same time being continually subjected to extremely rapid, high velocity impacts. The specimen is subjected to flexing, rubbing, shock, compression, stretching, and other mechanical forces during the test. Abrasion is produced throughout the specimen by rubbing of yarn against yarn, fibre against fibre, surface against surface and surface against abradant.

AATCC 94, Finishes in Textiles: Identification

This test method gives guidelines for qualitative identification of various finish components present on textile fabrics, yarns or fibres.

The identification scheme may involve any or all of the following approaches:

- Sequential solvent extractions followed by identification of extracts by infrared spectroscopy (IR), gas chromatography (GC), high performance liquid chromatography (HPLC), thin layer chromatography (TLC), nuclear magnetic resonance spectroscopy (NMR) or other instrumental or wet-chemical methods.

- Direct measure of elemental or chemical species on fabric by X-ray fluorescence spectroscopy, infrared reflectance spectroscopy, furnace atomic absorption spectroscopy, and other instrumental or wet-chemical analysis methods.

- Identification of specific finishing components by chemical spot tests on the textile or extracts from textiles.

This test method provides a quantitative procedure for the evaluation of the degree of antibacterial activity. Assessment of antibacterial activity finishes on textile material is determined by the degree of antibacterial activity intended in the use of such materials. If only bacteriostatic activity (inhibition of multiplication) is intended, a qualitative procedure that clearly demonstrates antibacterial activity as contrasted with lack of such activity by an untreated specimen may be acceptable. However, if bactericidal activity is intended or implied, quantitative evaluation is necessary. Quantitative evaluation also provides a clearer picture for possible uses of such treated textile materials.

AATCC 109, Colourfastness to Ozone in the Atmosphere Under Low Humidities

This test method is intended for determining the resistance of the colour of textiles to the action of ozone in the atmosphere at room temperatures with relative humidities not exceeding 67%.

A test specimen and a control specimen are simultaneously exposed to ozone in an atmosphere under ambient temperatures (64-82°F) and relative humidities not exceeding 67%, until the control specimen shows a colour change corresponding to that of a standard of fading. This exposure period constitutes one cycle. The cycle is repeated (1) until the specimen shows a definite colour change or (2) for a prescribed number of cycles.

AATCC 116, Colourfastness to Crocking: Rotary Vertical Crockmeter Method

This test method is used to determine the amount of colour transferred from the surface of coloured textile materials to other surfaces by rubbing. It is applicable to textiles made from all fibres in the form of yarn or fabric, whether dyed, printed, or otherwise coloured and especially to prints where the singling out of areas smaller than possible to test with the standard AATCC Crockmeter (AATCC Test Method 8) is required.

Test procedures employing test squares either dry or wet with water or other liquids are within the scope of this method.

A test specimen held at the base of the Rotary Vertical Crockmeter is rubbed with standard test squares under controlled conditions. Colour transferred to the test squares is assessed by comparison with the Gray Scale for Staining or AATCC Chromatic Transference Scale.

AATCC-118, Oil Repellency: Hydrocarbon Resistance Test

This test method is used to detect the presence of a fluorochemical finish, or other compounds capable of imparting a low energy surface, on all types of fabrics, by evaluating the fabric's resistance to wetting by a selected series of liquid hydrocarbons of different surface tensions.

Drops of standard test liquids, consisting of a selected series of hydrocarbons with varying surface tensions, are placed on the fabric surface and observed for wetting, wicking, and contact angle. The oil repellency grade is the highest numbered test liquid which does not wet the fabric surface.

AATCC 121, Carpet Soiling: Visual Rating Method

This test method covers the measurement of the degree of cleanness of pile floor coverings, in the range from clean to a middle degree of soiling. It can be used to measure the accumulation of soil, or the removal of soil by a cleaning procedure. It can be used with pile floor coverings of any colour, pattern, structure, or fibre content.

This test method does not evaluate structural appearance changes.

The degree of difference in cleanness between an original or clean area, and the area under examination is determined by visual matching with a stepwise series of differences in grey chips selected to form a geometrical scale of differences on the dark-light axis.

AATCC 122, Carpet Soiling: Service Soiling Method

This test method evaluates the service soiling of carpets and rugs.

Specimen of carpets and selected control samples are exposed to normal foot traffic in a controlled test area. The test specimens and controls are removed and visually rated at predetermined intervals corresponding to different degrees of soiling or exposure to soiling.

AATCC 123, Carpet Soiling: Accelerated Soiling Method

This test method describes a procedure for the accelerated soiling of carpets. It can be used to compare the soiling propensity of two or more carpets; or it can be used to soil carpets as a preliminary step in measuring either the ability of a carpet to be cleaned or the efficiency of a cleaning process. This accelerated carpet soiling method has been found to give similar results to floor service soiling, but its use is recommended only as a screening method and not as a replacement for floor testing.

Specimens of carpet are tumbled together with prepared synthetic soil in a laboratory ball mill for a predetermined time.

AATCC 129, Colourfastness to Ozone in the Atmosphere under High Humidities

This test method is used for determining the resistance of the colour of textiles to the action of ozone in the atmosphere at elevated temperatures with relative humidities above 85%.

A test specimen and a swatch of control sample are simultaneously exposed to ozone in an atmosphere which is maintained at 87.5 ± 2.5% relative humidity and a temperature of 40 ± 1 C (104 ± 2 F) until the control sample shows a colour change corresponding to that of a standard of fading. The cycles are repeated until the specimen shows a definite colour change or for a prescribed number of cycles.

On certain fibres, dye fading does not readily take place at humidities below 85%. Testing at high humidities is required to produce colour change that predicts service fading under warm, humid conditions.

AATCC 134, Electrostatic Propensity of Carpets

This test method assesses the static-generating propensity of carpets developed when a person walks across them by using a controlled laboratory simulation of conditions that may be encountered in practice. The simulation is focused on the use of those conditions known from experience to be strong contributors to excessive accumulation of static charges.

This test method does not include standards of performance. The specification requirements pertinent to any given application can vary considerably, depending on the specific demands of the application.

AATCC 138, Cleaning: Washing of Textile Floor Coverings

This test method is a laboratory procedure designed to simulate changes that occur in washing of a textile floor covering during cleaning.

This method is recommended only for small specimens with dimensions not exceeding the capacity of commercially available laboratory equipment.

This test method may be used on soiled, as well as unsoiled, textile floor coverings.

This wet cleaning procedure can be used for the evaluation of:

- wetfastness durability and permanency of antimicrobial properties.

- colourfastness behaviour.

- permanency of finishes and other topical treatments to the pile of textile floor coverings before, during or after manufacturing.

- cleanability.

- dimensional stability.

AATCC 165, Colourfastness to Crocking: Textile Floor Coverings - AATCC Crockmeter Method

This test method is designed to determine the degree of colour transfer from the surface of textile floor coverings to other surfaces by rubbing. The intent is to reproduce as nearly as possible true-to-life situations in all constructions whether dyed, printed or otherwise coloured.

Test procedures employing white test cloths, both dry and wet with water, are given. As the use surface of a textile floor covering may be exposed to various conditions in true-to-life situations, such as anti-soils, anti-stats, anti-microbials, etc., the test may be made before, after or before and after such situations.

AATCC 171, Carpets: Cleaning of; Hot Water Extraction Method

This test method provides a laboratory procedure to clean textile floor coverings by a technique simulating cleaning of installed floor coverings by hot water extraction, sometimes erroneously called "steam cleaning."

This test method may be used to clean a carpet in a manner that duplicates the most popular (70%) means of actual on-floor cleaning of carpets.

This test method prepares specimens that can be tested for many properties; e.g., colourfastness, dimensional stability, permanency of finishes, ease of cleaning, etc.

AATCC 174, Antimicrobial Activity Assessment of Carpets

This test method is designed to determine the antimicrobial activity of new carpet materials and consists of three procedures:

- A qualitative antibacterial assessment.

- A quantitative antibacterial assessment.

- A quantitative antifungal assessment.

AATCC 175, Stain Resistance: Pile Floor Coverings

This test method is intended for use on pile floor coverings to determine the resistance to staining by acid food colours.

A specimen of pile floor covering is stained with a small volume of a diluted aqueous solution of Food Drug and Cosmetic (FD&C) Red 40 adjusted to an acid pH. After allowing the stained specimen to remain at controlled conditions for 24 ± 4 h, it is rinsed in water to remove all unused FD&C Red 40 dye. Any residual stain is assessed after drying.

AATCC 177, Colourfastness to Light at Elevated Temperature and Humidity: Xenon Lamp Apparatus

This test method provides the general principles and procedures which are currently in use for determining the colourfastness to light of textile materials that are used in extreme conditions of light, elevated temperature and humidity, such as trim material in automotive interiors. The test method described is applicable to materials of all kinds including applied colourants, finishes, and treatments.

The use of this test method does not imply, expressly or otherwise, an accelerated test for a specific application but does assist the user to predict performance of materials used in applications such as the interior of automobiles. The degree of correlation between any light-fastness test and the actual exposure in use must be determined mathematically and agreed upon by the contractual parties.

A specimen of the material to be tested and the agreed upon comparison standard(s) are exposed simultaneously to a light source under specified conditions. The colourfastness to light of the specimen is evaluated by determining the colour change of the exposed portion as measured before and after exposure of the test specimen, using the AATCC Gray Scale for Colour Change or by instrumental colour measurement.

AATCC 180, Colourfastness to Light at High Temperatures: Daylight Temperature Controlled Apparatus

This test method specifies the operating procedures for the exposure of automotive interior trim materials in an outdoor behind-glass apparatus in which the temperature is controlled for part of the day.

Specimen preparation, test durations, and performance evaluation procedures are covered in material specifications of the different automotive manufacturers.

Samples of the textile material to be tested and the agreed upon comparison standard(s) are exposed simultaneously under specified conditions designed to accelerate the amount of irradiance imposed upon the specimens. The amount of exposure is determined with respect to a specified degree of colour change, or alternately to a specific amount of radiant energy. The colourfastness of the specimen is evaluated by comparison of the colour change of the exposed portion of the test specimen or the unexposed original material, using the AATCC Gray Scale for Colour Change or by instrumental colour measurement.