BB1A - GLOSSARY - RESILIENT FLOORING

A

above grade

Refer to "grade".

above grade

Refer to "grade".

abrasion

Wearing, grinding, or rubbing away by friction.

abrasion resistance

This is the resistance to wear in which the gradual removal of a flooring surface is caused by friction action of relatively fine particles (e.g. foot traffic, dirt, etc.). Abrasion resistance generally depends on the toughness of the product or wear layer, thickness of wear layer, and existence of surface coatings.

acclimation acclimatization

Adaptation of resilient flooring materials to their installed temperature and humidity environment (i.e., not work-site environment which may be different). Such materials should be unpacked and allowed enough time (generally 48 hours) to equalize to these requirements.

acid

Chemical substance rated below 7 on the pH scale

acid etch

Refers to the use of a mixture of muriatic acid and water on concrete either to neutralize the surface if it shows signs of alkali or to open the surface to allow a good bond with adhesives or powder underlayments. This can actually cause problems in bonding due to acid residue.

acoustics

The sounds of floor traffic and dropped objects are important when considering types of flooring materials. The cushioning of impacts reduces the generation of airborne sound within the room and the level of sound that can be transmitted to adjacent areas. It also minimizes the transmission of impact-generated, structure-borne noises throughout the building. In multi-family dwellings, the transmission of impact-generated noise is of primary concern. Resilient flooring, in general, "gives" under the impact of footsteps, dropped objects, and rolling loads. The resilience helps to reduce traffic noise. In comparison with other hard-surfaced flooring (wood, marble, ceramic, concrete, metal), resilient floors are low noise producers.

acoustical properties

Absorbance, reflection, or transmission of sound waves.

across machine direction

The direction perpendicular to which a flooring product moves through the manufacturing process.

adhesion

This is the property that causes one material to stick to another. Adhesion is affected by the condition of the surface to be coated and by the closeness of contact, as well as by the molecular forces of unlike substances. Substrate surfaces and floor backings should allow a certain amount of penetration, and should be clean, and not too smooth, hard, or nonporous for good adhesion.

adhesive

A substance that dries to a film and capable of holding materials together by surface attachment. Adhesives may be applied to the substrate by using a trowel, airless spray, roller, or other means acceptable to the adhesive manufacturer. Refer also to Part B04C – Material Guide (resilient flooring) and Part A14 - Adhesives and Fastenings for additional information.

adhesive bleeding

This is the undesired migration of materials in the adhesive to the surface of the floor between flooring joints or seams.

adhesive transfer

The amount of adhesive actually "transferred" into the back of flooring that will provide adhesive contact with the substrate. 100% adhesive transfer is total contact of the adhesive to flooring.

adsorption

A type of adhesion that occurs at the surface of a solid or liquid in contact with another medium, thus allowing an increased number of molecules of the gas or liquid to become attached to the surface of the solid at the point of contact.

aesthetics

Properties perceived by sight such as the colour, pattern, and texture of flooring.

air bubbles

These are caused by air trapped under the flooring and can be small or large in size. These may occur shortly after installation and are caused by placing the flooring into the adhesive too soon or rolling improperly. When they appear at a later time, they may be caused by moisture in the substrate.

alkali

Alkalis are also referred to as bases. They are a soluble substance having a pH of more than 7 when dissolved in water.

alkaline salts

These occur in concrete, and may be left as a residue on substrate surfaces when the water carrying alkaline salts evaporates during the concrete curing process. The presence of alkaline salt will cause adhesive bonding and/ or flooring material failures.

alkalinity

A measurement of alkaline rated above 7 on the pH scale.

alkalinity test

A test using litmus paper or other means to determine the alkalinity (pH) level of a material such as a concrete substrate before deciding on the feasibility of gluing a floor covering material directly to it.

ashlar

A term used to describe the layout pattern of floor tiles (or substrate or underlayment panels) in relation to every other row such as half-staggered or brick-pattern design, e.g. the joints in one course (row) of tile fall directly in the centre of each tile in adjacent rows.

Wearing, grinding, or rubbing away by friction.

abrasion resistance

This is the resistance to wear in which the gradual removal of a flooring surface is caused by friction action of relatively fine particles (e.g. foot traffic, dirt, etc.). Abrasion resistance generally depends on the toughness of the product or wear layer, thickness of wear layer, and existence of surface coatings.

acclimation acclimatization

Adaptation of resilient flooring materials to their installed temperature and humidity environment (i.e., not work-site environment which may be different). Such materials should be unpacked and allowed enough time (generally 48 hours) to equalize to these requirements.

acid

Chemical substance rated below 7 on the pH scale

acid etch

Refers to the use of a mixture of muriatic acid and water on concrete either to neutralize the surface if it shows signs of alkali or to open the surface to allow a good bond with adhesives or powder underlayments. This can actually cause problems in bonding due to acid residue.

acoustics

The sounds of floor traffic and dropped objects are important when considering types of flooring materials. The cushioning of impacts reduces the generation of airborne sound within the room and the level of sound that can be transmitted to adjacent areas. It also minimizes the transmission of impact-generated, structure-borne noises throughout the building. In multi-family dwellings, the transmission of impact-generated noise is of primary concern. Resilient flooring, in general, "gives" under the impact of footsteps, dropped objects, and rolling loads. The resilience helps to reduce traffic noise. In comparison with other hard-surfaced flooring (wood, marble, ceramic, concrete, metal), resilient floors are low noise producers.

acoustical properties

Absorbance, reflection, or transmission of sound waves.

across machine direction

The direction perpendicular to which a flooring product moves through the manufacturing process.

adhesion

This is the property that causes one material to stick to another. Adhesion is affected by the condition of the surface to be coated and by the closeness of contact, as well as by the molecular forces of unlike substances. Substrate surfaces and floor backings should allow a certain amount of penetration, and should be clean, and not too smooth, hard, or nonporous for good adhesion.

adhesive

A substance that dries to a film and capable of holding materials together by surface attachment. Adhesives may be applied to the substrate by using a trowel, airless spray, roller, or other means acceptable to the adhesive manufacturer. Refer also to Part B04C – Material Guide (resilient flooring) and Part A14 - Adhesives and Fastenings for additional information.

adhesive bleeding

This is the undesired migration of materials in the adhesive to the surface of the floor between flooring joints or seams.

adhesive transfer

The amount of adhesive actually "transferred" into the back of flooring that will provide adhesive contact with the substrate. 100% adhesive transfer is total contact of the adhesive to flooring.

adsorption

A type of adhesion that occurs at the surface of a solid or liquid in contact with another medium, thus allowing an increased number of molecules of the gas or liquid to become attached to the surface of the solid at the point of contact.

aesthetics

Properties perceived by sight such as the colour, pattern, and texture of flooring.

air bubbles

These are caused by air trapped under the flooring and can be small or large in size. These may occur shortly after installation and are caused by placing the flooring into the adhesive too soon or rolling improperly. When they appear at a later time, they may be caused by moisture in the substrate.

alkali

Alkalis are also referred to as bases. They are a soluble substance having a pH of more than 7 when dissolved in water.

alkaline salts

These occur in concrete, and may be left as a residue on substrate surfaces when the water carrying alkaline salts evaporates during the concrete curing process. The presence of alkaline salt will cause adhesive bonding and/ or flooring material failures.

alkalinity

A measurement of alkaline rated above 7 on the pH scale.

alkalinity test

A test using litmus paper or other means to determine the alkalinity (pH) level of a material such as a concrete substrate before deciding on the feasibility of gluing a floor covering material directly to it.

ashlar

A term used to describe the layout pattern of floor tiles (or substrate or underlayment panels) in relation to every other row such as half-staggered or brick-pattern design, e.g. the joints in one course (row) of tile fall directly in the centre of each tile in adjacent rows.

asphalt tile

Resilient flooring composed of a thermoplastic binder, mineral and asbestos fibres, and pigments. The binder is essentially asphalt or hydrocarbon resins, or both of coal tar and petroleum origin compounded with suitable plasticizers and stabilizers.

Resilient flooring composed of a thermoplastic binder, mineral and asbestos fibres, and pigments. The binder is essentially asphalt or hydrocarbon resins, or both of coal tar and petroleum origin compounded with suitable plasticizers and stabilizers.

B

backing

An integral, non-textile solid or foam backing layer that determines what adhesive will be used for installation over various substrates.

Backing may be:

- cushioned backing: an integral backing added to improve the comfort characteristics of the flooring and also to aid in acoustical performance.

- integral backing: a general term used for a layer or combination of layers that: may be located on the back of the material, of a texture differing considerably from that of the surface layer, and/or a layer that acts at least partially as a reinforcement.

- underfelt backing: a resilient textile backing layer, usually applied to hide minor substrate imperfections from telegraphing through to the top layer of flooring and also to aid in acoustical performance.

balling

A condition that occurs during application of adhesive when it "balls up" under the trowel. This is usually due to a dusty or dirty substrate or may also occur when the adhesive has been frozen.

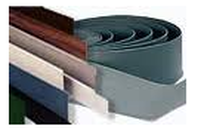

base or baseboard

Separate flat or shaped, extruded or moulded vinyl or rubber, or wood board skirting or integral resilient flooring attached to the wall or counter base surfaces to cover the joint of the wall and the adjoining floor.

below grade

Refer to "grade".

binder

The composition of a plastic that contains the resin, plasticizer and stabilizer; whatever is not binder is filler.

bloom

The term given to minor colour change linoleum flooring undergoes when it is exposed to light. This is due to the oxidation of the linseed oil and results in a yellowish cast when it is not exposed to light (under appliances or other floor coverings (e.g. a rug). This visual discolouration is only temporary as once exposed to light the yellowing disappears.

bond

The adherence of one material to another.

bond test

A 72-hour test to determine if resilient flooring can be adhered to the subfloor with the recommended adhesive. The test determines whether the adhesive is compatible with the subfloor and can also detect the presence of moisture. Bond testing determines the compatibility of adhesive with sealers, curing agents and other foreign matter and determines the necessity of their removal.

borders

A perimeter band usually of the same flooring material but of a different colour used to frame the field colour and customize a flooring installation.

buckling

The same as wrinkles, or other deviations from lying flat.

bullnose

Common term used for a stair tread nosing or step return.

A condition that occurs during application of adhesive when it "balls up" under the trowel. This is usually due to a dusty or dirty substrate or may also occur when the adhesive has been frozen.

base or baseboard

Separate flat or shaped, extruded or moulded vinyl or rubber, or wood board skirting or integral resilient flooring attached to the wall or counter base surfaces to cover the joint of the wall and the adjoining floor.

below grade

Refer to "grade".

binder

The composition of a plastic that contains the resin, plasticizer and stabilizer; whatever is not binder is filler.

bloom

The term given to minor colour change linoleum flooring undergoes when it is exposed to light. This is due to the oxidation of the linseed oil and results in a yellowish cast when it is not exposed to light (under appliances or other floor coverings (e.g. a rug). This visual discolouration is only temporary as once exposed to light the yellowing disappears.

bond

The adherence of one material to another.

bond test

A 72-hour test to determine if resilient flooring can be adhered to the subfloor with the recommended adhesive. The test determines whether the adhesive is compatible with the subfloor and can also detect the presence of moisture. Bond testing determines the compatibility of adhesive with sealers, curing agents and other foreign matter and determines the necessity of their removal.

borders

A perimeter band usually of the same flooring material but of a different colour used to frame the field colour and customize a flooring installation.

buckling

The same as wrinkles, or other deviations from lying flat.

bullnose

Common term used for a stair tread nosing or step return.

C

calendaring

A manufacturing process whereby the component mixture of flooring is poured from the mixer and placed on to a large continuous sheet and/or between two large, hot, rotating rolls and allowing the mass to be squeezed into a thin sheet; similar to a dough roller.

capping

Material used to finish the vertical top edge of floor covering.

chemical resistance

This is the ability of a flooring product to resist softening, bleaching or discoloration from common chemicals that may be spilled on the floor. Chemical resistance is most dependent on the composition of the product, the existence and chemistry of the surface coating and the susceptibility of the seams to failure in chemical spills.

chemically welded seam

This is a seam produced by applying adhesive to and abutting the edges of resilient flooring to provide a bond and seal. Excess material is cleaned off the finished flooring surface after application.

colour change

This is a visual change in the colour of the flooring caused by exposure to light, deprivation of light and air, or some chemical reaction.

calendaring

A manufacturing process whereby the component mixture of flooring is poured from the mixer and placed on to a large continuous sheet and/or between two large, hot, rotating rolls and allowing the mass to be squeezed into a thin sheet; similar to a dough roller.

capping

Material used to finish the vertical top edge of floor covering.

chemical resistance

This is the ability of a flooring product to resist softening, bleaching or discoloration from common chemicals that may be spilled on the floor. Chemical resistance is most dependent on the composition of the product, the existence and chemistry of the surface coating and the susceptibility of the seams to failure in chemical spills.

chemically welded seam

This is a seam produced by applying adhesive to and abutting the edges of resilient flooring to provide a bond and seal. Excess material is cleaned off the finished flooring surface after application.

colour change

This is a visual change in the colour of the flooring caused by exposure to light, deprivation of light and air, or some chemical reaction.

colour fastness

This is the ability of a floor covering material to resist change in colour due to exposure to strong sunlight. Such exposure may affect the performance and appearance of the floor due to fading, shrinking, or blistering. Because of this most resilient floors are not recommended for outdoor installation.

combustible

Having a flash point of 27 - 65°C (80 - 150°F).

commercial flooring

This is resilient flooring designed for installation in commercial settings such as schools, hospitals, public buildings and institutions. Such flooring may also be referred to as contract flooring. Refer also to residential flooring.

conductive floor covering

Electrically conductive resilient flooring specially formulated to prevent the build up of static charges. This line of floor covering must conform to CAN/CGSB 81-GP-1M. To retain the conductive nature of all Static Control Floors, wax must not be applied, including all adjacent areas up to a minimum of 15000 mm. There are three (3) different levels of static control floor covering currently available:

This is the ability of a floor covering material to resist change in colour due to exposure to strong sunlight. Such exposure may affect the performance and appearance of the floor due to fading, shrinking, or blistering. Because of this most resilient floors are not recommended for outdoor installation.

combustible

Having a flash point of 27 - 65°C (80 - 150°F).

commercial flooring

This is resilient flooring designed for installation in commercial settings such as schools, hospitals, public buildings and institutions. Such flooring may also be referred to as contract flooring. Refer also to residential flooring.

conductive floor covering

Electrically conductive resilient flooring specially formulated to prevent the build up of static charges. This line of floor covering must conform to CAN/CGSB 81-GP-1M. To retain the conductive nature of all Static Control Floors, wax must not be applied, including all adjacent areas up to a minimum of 15000 mm. There are three (3) different levels of static control floor covering currently available:

- anti-static flooring: flooring with a static resistance of less than 1014 _ but more than 109_

- dissipative flooring: flooring with a static resistance of less than 100_ but more than 106_

conductive flooring: flooring with a static resistance of less than 106_ but more than 2.5 x 104_

cork tile

A floor surfacing material made from natural cork granules of different sizes and densities thoroughly and uniformly bonded with resin binders. Made in tile form, with or without an attached backing. Because it is a wood based material some categorize this material as wood flooring. Refer also to -0 00Other Flooring.

cove base (resilient)

This type of base is made of vinyl or rubber and is available in a variety of sizes, shapes, and colours and conforms to requirements of ASTM F1861. Refer also to base.

A floor surfacing material made from natural cork granules of different sizes and densities thoroughly and uniformly bonded with resin binders. Made in tile form, with or without an attached backing. Because it is a wood based material some categorize this material as wood flooring. Refer also to -0 00Other Flooring.

cove base (resilient)

This type of base is made of vinyl or rubber and is available in a variety of sizes, shapes, and colours and conforms to requirements of ASTM F1861. Refer also to base.

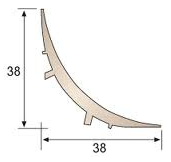

cove former

This is purpose-made filler made of wood, plastic, or wax which is placed at the juncture of the floor and wall to support sheet flooring that is flash coved. If there is no support behind the cove, the flooring can be punctured or might crack.

This is purpose-made filler made of wood, plastic, or wax which is placed at the juncture of the floor and wall to support sheet flooring that is flash coved. If there is no support behind the cove, the flooring can be punctured or might crack.

coving

Also referred to as flash or self-coving. Floor covering materials installed over a cove former to vertical surfaces to a specified height.

Also referred to as flash or self-coving. Floor covering materials installed over a cove former to vertical surfaces to a specified height.

creasing cross seam

The formation of folds, wrinkles or ridges in sheet flooring prior to installation. A seam across the width of the material to form a continuous length.

curing / agents

Used on concrete subfloors. The residue of concrete curing and sealing agents is generally incompatible with most floor covering adhesives and must be removed prior to adhesive / flooring installation.

cushion-backed flooring

Resilient cushion / padding material bonded to the underside of sheet flooring materials to provide softness, noise absorption, and adequate support when it is walked upon. Cushion-backed material provides a softer feel underfoot and provides added acoustical and insulation benefits.

cushioned vinyl flooring

A vinyl sheet floor covering where a foam layer is incorporated as part of the product.

cut

A length of resilient flooring cut from a full roll to fill an order.

cutback adhesive

This refers to asphalt adhesive that has been liquefied with petroleum solvents. When the lighter fractions are boiled away from petroleum oil, the thick residue left is asphalt. To make it fluid again, solvent is added and the asphalt is "cut back."

The formation of folds, wrinkles or ridges in sheet flooring prior to installation. A seam across the width of the material to form a continuous length.

curing / agents

Used on concrete subfloors. The residue of concrete curing and sealing agents is generally incompatible with most floor covering adhesives and must be removed prior to adhesive / flooring installation.

cushion-backed flooring

Resilient cushion / padding material bonded to the underside of sheet flooring materials to provide softness, noise absorption, and adequate support when it is walked upon. Cushion-backed material provides a softer feel underfoot and provides added acoustical and insulation benefits.

cushioned vinyl flooring

A vinyl sheet floor covering where a foam layer is incorporated as part of the product.

cut

A length of resilient flooring cut from a full roll to fill an order.

cutback adhesive

This refers to asphalt adhesive that has been liquefied with petroleum solvents. When the lighter fractions are boiled away from petroleum oil, the thick residue left is asphalt. To make it fluid again, solvent is added and the asphalt is "cut back."

D

damp mopping

This procedure involves the removal of fine dust, grit, and spills from the floor surface with a mop dampened with a neutral detergent solution. Performed daily, this procedure helps to control grit and can reduce time and money spent on more intensive maintenance procedures.

dimensional stability

The ability of resilient flooring to retain its original size and shape during the service life of the product. This property is usually measured by:

double cut

A method of cutting a seam in sheet floor covering.

drop match

In sheet goods, a matching of pattern design in adjacent sheet widths or in successive sheet lengths to present an uninterrupted pattern. In side matching the sheet is adjusted up or down to align the pattern.

dusting

Appearance of a powdery material on the surface of newly hardened concrete. Sometimes caused by allowing the surface to dry too rapidly without curing. This condition must be corrected before installing resilient flooring.

E

ease of cleaning

Refers to cleanability of resilient flooring which is dependent on the porosity of the surface that provides voids for dirt entrapment, presence of surface coatings, uniform coverage of the coating, and toughness of the surface coating to stand-up to wear and maintenance routines.

edge trim

Metal or vinyl moulded or extruded edging material designed for installation at exposed edges of resilient floor covering to protect edges from damage.

embossed

Permanent raised or indented designs in flooring that stand out, as if engraved. These are produced by mechanical or chemical means during manufacturing. Embossing provides a three-dimensional appearance and helps conceal substrate irregularities. They also prolong gloss retention because only the high points of the embossing are exposed to surface abrasion.

end

A short length of resilient flooring or a remnant from a complete roll.

epoxy adhesive

A very strong two-part thermo set adhesive that is mixed on the job. Depending on the use, epoxies can have a short or long working time or pot life.

expansion joint

These are separations between adjoining parts of floor construction (usually in a concrete slab) that allow separate movement of the parts. They are usually filled with an elastomeric type of material and should never be filled with a cementitious underlayment product because any movement of the separate parts may cause the underlayment to break up and be pushed out of the joint. Resilient flooring should not be installed over this type of joint as cracking and buckling may occur. Expansion joint covers should be used instead.

external corner

On-site installed wrapped or mitred base corner.

F

fading

Loss of colour caused by sunlight, artificial light, atmospheric gases or certain chemicals (e.g. household cleaning, swimming pool chlorine, etc.). Installations in areas where such exposures may occur require extreme care in the selection of an appropriate resilient floor covering.

fastness

The resistance to fading or change in colour. Also referred to as colourfastness.

feathering

A sub-floor preparation procedure for tapering patching materials.

feature strips

Contrasting strips or shapes of floor covering material used as borders or to delineate pattern for decorative or functional purpose (as in gymnasium or multi-purpose game situations).

field

The area of resilient flooring that is contained within walls or border limits.

filler

Material used to level substrate surfaces. Refer also to Part A13 - Patching and Filling.

fillet strip, or cove backing / former

Structural backing for flash coving. See also "cove former".

flame resistant

A term used to describe a material that burns slowly or is self-extinguishing after removal of an external source of ignition. Resilient flooring can be flame resistant because of the chemical properties of the material.

flame spread

The propagation of a flame away from the source of ignition across a flooring surface.

flammable

Having a flash point of 7 - 27°C (20 - 80°F).

flammability

The ability of a resilient floor covering to burn with a flame under specified test conditions. Refer also to Part A08A - Flammability Issues.

flash coving

Refer to coving.

flexibility

The property of a resilient flooring that allows it to be deformed by bending or rolling without cracking, breaking, or showing other permanent defects.

floating floor

A residential installation procedure where the sheet flooring is loose laid over an acceptable substrate surface without the use of fasteners. Such flooring may be spot glued at the perimeter.

floor machine

Refer to Part BB1B - Glossary - Tools (for resilient flooring).

floor machine brush

Refer to Part BB1B - Glossary - Tools (for resilient flooring).

floor machine pad

Refer to Part BB1B - Glossary - Tools (for resilient flooring).

floor protectors

Screw-on attachments for the bottom of chair and table legs to distribute the weight of furniture evenly to reduce indentations in resilient floors. Abrasions can be prevented with unique, replaceable felt pads on the floor protectors.

foam backed sheet vinyl

Vinyl (PVC) sheet goods, with an attached expanded cellular foam backing. Refer also to cushioned backed flooring.

full roll

A complete roll of resilient flooring with the length and width of the roll dependent on the material / manufacturer.

full spread installation

A procedure for installing sheet goods or tiles using adhesive over the entire substrate area.

funnel area

An area where foot traffic is concentrated, such as doorways, stairwells, in front of drinking fountains, etc.

G

gauge

Thickness of a flooring material or of a layer within the material. With resilient flooring, wear layer and backing gauge are often listed separately.

gloss level

The degree of shine (e.g., satin, semi-gloss, gloss) of the flooring material or applied finish.

gouge

A form of wear consisting of a wide groove deformation accompanied by material removal and penetration a considerable distance below the immediate flooring surface.

grab

The property that enables an adhesive film to hold in place an adherent that is trying to pull away. This is usually applied to a partially set film.

grade

A degree of quality.

OR

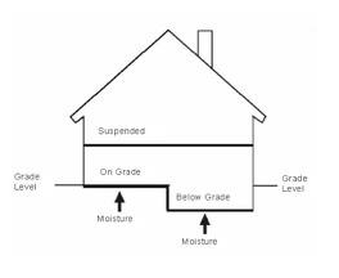

grade

The relationship of a substrate to the exterior ground or grade level. There are three categories:

heat-welded seam

This is a seam produced by grooving abutting edges of resilient flooring and filling the groove with heated, fused or melted material (usually from a weld rod) to provide a bond and seal. Excess welding material is trimmed flush with the finished flooring after cooling.

damp mopping

This procedure involves the removal of fine dust, grit, and spills from the floor surface with a mop dampened with a neutral detergent solution. Performed daily, this procedure helps to control grit and can reduce time and money spent on more intensive maintenance procedures.

dimensional stability

The ability of resilient flooring to retain its original size and shape during the service life of the product. This property is usually measured by:

- temperature induced dimensional change: the alteration in lineal dimensions as a result of exposure to significant variation in temperature followed by a return to original conditions, or

- moisture induced dimensional change: the alteration in dimensions as a result of exposure to a significant variation in moisture.

double cut

A method of cutting a seam in sheet floor covering.

drop match

In sheet goods, a matching of pattern design in adjacent sheet widths or in successive sheet lengths to present an uninterrupted pattern. In side matching the sheet is adjusted up or down to align the pattern.

dusting

Appearance of a powdery material on the surface of newly hardened concrete. Sometimes caused by allowing the surface to dry too rapidly without curing. This condition must be corrected before installing resilient flooring.

E

ease of cleaning

Refers to cleanability of resilient flooring which is dependent on the porosity of the surface that provides voids for dirt entrapment, presence of surface coatings, uniform coverage of the coating, and toughness of the surface coating to stand-up to wear and maintenance routines.

edge trim

Metal or vinyl moulded or extruded edging material designed for installation at exposed edges of resilient floor covering to protect edges from damage.

embossed

Permanent raised or indented designs in flooring that stand out, as if engraved. These are produced by mechanical or chemical means during manufacturing. Embossing provides a three-dimensional appearance and helps conceal substrate irregularities. They also prolong gloss retention because only the high points of the embossing are exposed to surface abrasion.

end

A short length of resilient flooring or a remnant from a complete roll.

epoxy adhesive

A very strong two-part thermo set adhesive that is mixed on the job. Depending on the use, epoxies can have a short or long working time or pot life.

expansion joint

These are separations between adjoining parts of floor construction (usually in a concrete slab) that allow separate movement of the parts. They are usually filled with an elastomeric type of material and should never be filled with a cementitious underlayment product because any movement of the separate parts may cause the underlayment to break up and be pushed out of the joint. Resilient flooring should not be installed over this type of joint as cracking and buckling may occur. Expansion joint covers should be used instead.

external corner

On-site installed wrapped or mitred base corner.

F

fading

Loss of colour caused by sunlight, artificial light, atmospheric gases or certain chemicals (e.g. household cleaning, swimming pool chlorine, etc.). Installations in areas where such exposures may occur require extreme care in the selection of an appropriate resilient floor covering.

fastness

The resistance to fading or change in colour. Also referred to as colourfastness.

feathering

A sub-floor preparation procedure for tapering patching materials.

feature strips

Contrasting strips or shapes of floor covering material used as borders or to delineate pattern for decorative or functional purpose (as in gymnasium or multi-purpose game situations).

field

The area of resilient flooring that is contained within walls or border limits.

filler

Material used to level substrate surfaces. Refer also to Part A13 - Patching and Filling.

fillet strip, or cove backing / former

Structural backing for flash coving. See also "cove former".

flame resistant

A term used to describe a material that burns slowly or is self-extinguishing after removal of an external source of ignition. Resilient flooring can be flame resistant because of the chemical properties of the material.

flame spread

The propagation of a flame away from the source of ignition across a flooring surface.

flammable

Having a flash point of 7 - 27°C (20 - 80°F).

flammability

The ability of a resilient floor covering to burn with a flame under specified test conditions. Refer also to Part A08A - Flammability Issues.

flash coving

Refer to coving.

flexibility

The property of a resilient flooring that allows it to be deformed by bending or rolling without cracking, breaking, or showing other permanent defects.

floating floor

A residential installation procedure where the sheet flooring is loose laid over an acceptable substrate surface without the use of fasteners. Such flooring may be spot glued at the perimeter.

floor machine

Refer to Part BB1B - Glossary - Tools (for resilient flooring).

floor machine brush

Refer to Part BB1B - Glossary - Tools (for resilient flooring).

floor machine pad

Refer to Part BB1B - Glossary - Tools (for resilient flooring).

floor protectors

Screw-on attachments for the bottom of chair and table legs to distribute the weight of furniture evenly to reduce indentations in resilient floors. Abrasions can be prevented with unique, replaceable felt pads on the floor protectors.

foam backed sheet vinyl

Vinyl (PVC) sheet goods, with an attached expanded cellular foam backing. Refer also to cushioned backed flooring.

full roll

A complete roll of resilient flooring with the length and width of the roll dependent on the material / manufacturer.

full spread installation

A procedure for installing sheet goods or tiles using adhesive over the entire substrate area.

funnel area

An area where foot traffic is concentrated, such as doorways, stairwells, in front of drinking fountains, etc.

G

gauge

Thickness of a flooring material or of a layer within the material. With resilient flooring, wear layer and backing gauge are often listed separately.

gloss level

The degree of shine (e.g., satin, semi-gloss, gloss) of the flooring material or applied finish.

gouge

A form of wear consisting of a wide groove deformation accompanied by material removal and penetration a considerable distance below the immediate flooring surface.

grab

The property that enables an adhesive film to hold in place an adherent that is trying to pull away. This is usually applied to a partially set film.

grade

A degree of quality.

OR

grade

The relationship of a substrate to the exterior ground or grade level. There are three categories:

- above grade: a substrate with more than 450 mm (18") of well-ventilated space between the lower side of the floor structure and any point of the exterior grade level. Where an interior slab-on-grade is more than 200 mm (8") above the exterior grade level it may be considered as above grade.

- on grade: a substrate in direct contact with ground or structural fill, as in a slab-on-grade. This substrate may be located above or below the exterior grade level.

- below grade: a substrate located below exterior grade (as in a basement slab-on-grade) or a substrate with less than 450 mm (18") of well-ventilated space between the lower side of the floor structure (e.g. wood joists and subfloor) and interior grade (as in a crawl space).

heat-welded seam

This is a seam produced by grooving abutting edges of resilient flooring and filling the groove with heated, fused or melted material (usually from a weld rod) to provide a bond and seal. Excess welding material is trimmed flush with the finished flooring after cooling.

heterogenous flooring

Resilient flooring that consists of a wear layer and other compact layer(s) of different composition and/or design, one of which may be a reinforced backing layer. Sometimes called layered composite or backed vinyl sheet flooring, this flooring meets ASTM F1303 requirements

Resilient flooring that consists of a wear layer and other compact layer(s) of different composition and/or design, one of which may be a reinforced backing layer. Sometimes called layered composite or backed vinyl sheet flooring, this flooring meets ASTM F1303 requirements

homogenous flooring

Resilient flooring that consists of a single layer of material whose composition, colour, and pattern extends throughout the total depth of the material. Such flooring may be complete with or without a reinforced backing layer. Sometimes called unbacked vinyl sheet flooring, this flooring meets ASTM F1913 requirements.

Resilient flooring that consists of a single layer of material whose composition, colour, and pattern extends throughout the total depth of the material. Such flooring may be complete with or without a reinforced backing layer. Sometimes called unbacked vinyl sheet flooring, this flooring meets ASTM F1913 requirements.

hot-melt adhesive

An adhesive specially formulated and placed on the back of resilient tile so it can be installed without spreading any other adhesive products. This is normally used on tile commonly referred to as Place-n-Press, and is sold to the do-it-yourself (DIY) market.

hot-melt calendaring

New technology used to melt a vinyl wear layer into the calendar and immediately place it onto a calendared backing material for a composite structure.

humidity

The amount of water vapour in the air. See Relative Humidity.

hydrostatic pressure

Rising ground water forced under pressure through a concrete slab which may cause problems with floor installation.

I

impact load

These are momentary loads such as those produced from walking traffic that may indent flooring surfaces depending on the resilience of the flooring material. These impact pressures are high (often as much as several thousand pounds per square inch), and the smaller or sharper the impact area, the more damaging the indentation. High heel or spike shoes exert extremely high forces (1,000 psi [70.3 kg/sq cm] or more) and may visibly damage flooring. Refer also to rolling loads and static loads.

impact test

This is a test for determining the resistance of a flooring to impact by dropping a weight onto the flooring / finish.

indoor air quality

The quality of air (and environment) within a building. It is dependent on good building design, implementation of effective building systems, operations, and maintenance programs, and the appropriate selection of low VOC and odour emitting interior products. Refer to NFCA Manual Part A09 – Environmental Issues.

inlaid flooring

A floor covering in which a decorative pattern or design is formed by plain or coloured particles that may or may not extend through to the floor backing.

insert (also inset)

Custom or standard shape flooring elements / pieces in contrasting colour or pattern, set into the field of resilient floor covering for special purposes or effects.

An adhesive specially formulated and placed on the back of resilient tile so it can be installed without spreading any other adhesive products. This is normally used on tile commonly referred to as Place-n-Press, and is sold to the do-it-yourself (DIY) market.

hot-melt calendaring

New technology used to melt a vinyl wear layer into the calendar and immediately place it onto a calendared backing material for a composite structure.

humidity

The amount of water vapour in the air. See Relative Humidity.

hydrostatic pressure

Rising ground water forced under pressure through a concrete slab which may cause problems with floor installation.

I

impact load

These are momentary loads such as those produced from walking traffic that may indent flooring surfaces depending on the resilience of the flooring material. These impact pressures are high (often as much as several thousand pounds per square inch), and the smaller or sharper the impact area, the more damaging the indentation. High heel or spike shoes exert extremely high forces (1,000 psi [70.3 kg/sq cm] or more) and may visibly damage flooring. Refer also to rolling loads and static loads.

impact test

This is a test for determining the resistance of a flooring to impact by dropping a weight onto the flooring / finish.

indoor air quality

The quality of air (and environment) within a building. It is dependent on good building design, implementation of effective building systems, operations, and maintenance programs, and the appropriate selection of low VOC and odour emitting interior products. Refer to NFCA Manual Part A09 – Environmental Issues.

inlaid flooring

A floor covering in which a decorative pattern or design is formed by plain or coloured particles that may or may not extend through to the floor backing.

insert (also inset)

Custom or standard shape flooring elements / pieces in contrasting colour or pattern, set into the field of resilient floor covering for special purposes or effects.

L

laminated

Two or more layers of firmly united material.

latex patching compond

A patching and/or levelling compound consisting of latex (usually SBR rubber), Portland cement, and aggregate that is moisture, mildew, and alkali resistant.

lap back (or tube)

This refers to the process of "folding back" half the flooring sheet that has beendry laid to apply adhesive to the substrate. Care must be taken to avoid sharp kinks or creases in the material. An additional length allowance may be necessary during this process to accommodate for the compaction of flooring while it has been rolled back.

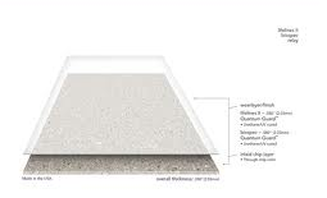

layers

The structure or composition of some types of resilient flooring may consist of a number of layers. Some of these may be a clear finish layer, a solid internal layer, and a backing layer. Such flooring is defined as heterogenous as opposed to flooring that is the same throughout or homogenous.

layout lines

Lines chalked on a substrate surface to guide in accurately setting flooring seams, particularly tile.

LEED

Leadership in Energy and Environmental Design. Refer to Part A09 – Environmental Issues for LEED requirements.

level

A surface or line with all points at the same elevation, horizontally straight.

light reflectivity

The characteristics of a material that determines the degree or amount of light that will be reflected from its surface from any given angle. Reflectivity values are determined by measuring the percentage of light directed at any surface that is then reflected under standardized test conditions. As brightness and quality of light play an important role in the illumination of institutional, commercial and industrial facilities the light reflectivity ratings of resilient floors are important when taking the complete interior environment into consideration. Since a majority of resilient floors are made of combinations of different colours, these light reflectance figures are average values based on a large area of the pattern. The Illuminating Engineering Society of North America recommends that floors have a reflectance factor of 20% to 40% for optimal seeing areas in offices, 30% to 50% for school classrooms, and 20% to 30% for hospital operating rooms. Light reflectance should not be confused with gloss. Gloss can result in reflected glare from highly polished surfaces in the field of view.

linoleum

A floor covering material composed of linseed oil, natural and synthetic resins, granulated cork, wood flour, mineral and chemical pigments thoroughly blended and calendared to a backing of jute canvas (Hessian). Linoleum was invented in England in 1863 by Frederick Walton who coined the name linoleum from the Latin name linum which means flax and oleum which means oil.

linoleum bloom

Linoleum "seasoning bloom" (also known as drying room film) is a natural phenomenon caused by the properties of the desiccant oils. These produce a yellow film that forms on the linoleum during the drying process. Any change in the product's appearance because of this film is temporary and disappears when the flooring is exposed to light. The time required for seasoning bloom to disappear ranges from several hours to several weeks depending on the light source's intensity. The light exposure process that eliminates the film will continue even after protective floor polishes are applied, although polish may slow the process. On areas of linoleum not exposed to light, elimination of the yellow film will not occur.

loose-lay installation

A procedure approved by some resilient flooring manufacturers for specific types of resilient sheet flooring (usually residential types) where flooring is installed without the use of fasteners or adhesive. Refer to modified loose lay / perimeter installation. Also see modified loose lay installation.

M

machine direction

The direction in which a flooring product moves through the manufacturing process.

manufacturing defects

This includes all flooring defects or blemishes that produced in manufacturing.

mastic

A term relating to flooring adhesive and sometimes even to latex primers. It is normally associated with water-based products and is a catchall term.

match marks

Indicators on certain types of resilient floor covering to show pattern repeats, or directional graining.

matching

A matching of the flooring pattern or design in adjacent sheet widths or in successive roll lengths to present an uninterrupted pattern.

mineral fibre backing

Inlaid vinyl, rotogravure vinyl or other types of floor covering containing a laminated moisture and alkali-resistant backing.

modified loose lay / perimeter installation

A procedure for installing certain manufacturer's approved sheet goods wherebythe floor covering is fastened generally around the outer edges and seams only.

modular

A term used to describe larger tiles that are usually 460 mm (18") square.

moulding

Refer to "reducer strips".

mitre joint

A junction of two pieces of flooring (or other material) at an angle. Most mitre joints involve pieces at right angles to one another with their ends cut at 45 degrees to form the joint.

N

net seam

A net seam results from the proper setting of an underscriber and angle of the knife blade. If the blade is held at a true 90-degree angle to the floor, a net seam will result. Tilting the blade away from the edge will result in an open seam, while tilting toward the edge produces a too-tight seam.

neutral cleaner

A mild (pH of 6 to 8) detergent that does not contain any strongly alkaline materials and that is designed to remove soil, not floor polish.

nosing

The leading edge of a stair tread. It also refers to formed vinyl, rubber, or pre-finished metal edge material.

O

on-grade

Refer to "grade".

open time

The amount of time between the spreading of adhesive on a substrate and the placement of a floor covering material into the adhesive during which the adhesive will still bond.

laminated

Two or more layers of firmly united material.

latex patching compond

A patching and/or levelling compound consisting of latex (usually SBR rubber), Portland cement, and aggregate that is moisture, mildew, and alkali resistant.

lap back (or tube)

This refers to the process of "folding back" half the flooring sheet that has beendry laid to apply adhesive to the substrate. Care must be taken to avoid sharp kinks or creases in the material. An additional length allowance may be necessary during this process to accommodate for the compaction of flooring while it has been rolled back.

layers

The structure or composition of some types of resilient flooring may consist of a number of layers. Some of these may be a clear finish layer, a solid internal layer, and a backing layer. Such flooring is defined as heterogenous as opposed to flooring that is the same throughout or homogenous.

layout lines

Lines chalked on a substrate surface to guide in accurately setting flooring seams, particularly tile.

LEED

Leadership in Energy and Environmental Design. Refer to Part A09 – Environmental Issues for LEED requirements.

level

A surface or line with all points at the same elevation, horizontally straight.

light reflectivity

The characteristics of a material that determines the degree or amount of light that will be reflected from its surface from any given angle. Reflectivity values are determined by measuring the percentage of light directed at any surface that is then reflected under standardized test conditions. As brightness and quality of light play an important role in the illumination of institutional, commercial and industrial facilities the light reflectivity ratings of resilient floors are important when taking the complete interior environment into consideration. Since a majority of resilient floors are made of combinations of different colours, these light reflectance figures are average values based on a large area of the pattern. The Illuminating Engineering Society of North America recommends that floors have a reflectance factor of 20% to 40% for optimal seeing areas in offices, 30% to 50% for school classrooms, and 20% to 30% for hospital operating rooms. Light reflectance should not be confused with gloss. Gloss can result in reflected glare from highly polished surfaces in the field of view.

linoleum

A floor covering material composed of linseed oil, natural and synthetic resins, granulated cork, wood flour, mineral and chemical pigments thoroughly blended and calendared to a backing of jute canvas (Hessian). Linoleum was invented in England in 1863 by Frederick Walton who coined the name linoleum from the Latin name linum which means flax and oleum which means oil.

linoleum bloom

Linoleum "seasoning bloom" (also known as drying room film) is a natural phenomenon caused by the properties of the desiccant oils. These produce a yellow film that forms on the linoleum during the drying process. Any change in the product's appearance because of this film is temporary and disappears when the flooring is exposed to light. The time required for seasoning bloom to disappear ranges from several hours to several weeks depending on the light source's intensity. The light exposure process that eliminates the film will continue even after protective floor polishes are applied, although polish may slow the process. On areas of linoleum not exposed to light, elimination of the yellow film will not occur.

loose-lay installation

A procedure approved by some resilient flooring manufacturers for specific types of resilient sheet flooring (usually residential types) where flooring is installed without the use of fasteners or adhesive. Refer to modified loose lay / perimeter installation. Also see modified loose lay installation.

M

machine direction

The direction in which a flooring product moves through the manufacturing process.

manufacturing defects

This includes all flooring defects or blemishes that produced in manufacturing.

mastic

A term relating to flooring adhesive and sometimes even to latex primers. It is normally associated with water-based products and is a catchall term.

match marks

Indicators on certain types of resilient floor covering to show pattern repeats, or directional graining.

matching

A matching of the flooring pattern or design in adjacent sheet widths or in successive roll lengths to present an uninterrupted pattern.

mineral fibre backing

Inlaid vinyl, rotogravure vinyl or other types of floor covering containing a laminated moisture and alkali-resistant backing.

modified loose lay / perimeter installation

A procedure for installing certain manufacturer's approved sheet goods wherebythe floor covering is fastened generally around the outer edges and seams only.

modular

A term used to describe larger tiles that are usually 460 mm (18") square.

moulding

Refer to "reducer strips".

mitre joint

A junction of two pieces of flooring (or other material) at an angle. Most mitre joints involve pieces at right angles to one another with their ends cut at 45 degrees to form the joint.

N

net seam

A net seam results from the proper setting of an underscriber and angle of the knife blade. If the blade is held at a true 90-degree angle to the floor, a net seam will result. Tilting the blade away from the edge will result in an open seam, while tilting toward the edge produces a too-tight seam.

neutral cleaner

A mild (pH of 6 to 8) detergent that does not contain any strongly alkaline materials and that is designed to remove soil, not floor polish.

nosing

The leading edge of a stair tread. It also refers to formed vinyl, rubber, or pre-finished metal edge material.

O

on-grade

Refer to "grade".

open time

The amount of time between the spreading of adhesive on a substrate and the placement of a floor covering material into the adhesive during which the adhesive will still bond.

P

patching

Process of repairing holes, cracks, breaches, etc. in a floor substrate prior to installation of resilient flooring.

pattern matching

A procedure for ensuring correct alignment of patterned materials.

pH

A value representing the concentration of hydrogen ions in gram equivalents per litre used to indicate the acidity or alkalinity of a substance on a scale from 0 to 14 with 7 representing neutrality, numbers less than 7 increasing acidity, and numbers greater than 7 increasing alkalinity. Laboratory and field testing for pH must be done with distilled water.

Special oils developed to impart flexibility and special properties like stain resistance to plastics, like PVC; they are added in the compounding step to the vinyl resin. The most common plasticizer used in vinyl is dioctyl phthalate (pronounced "die-octil-thal-ate") or DOP.

plasticizer migration

The migration of the plasticizer in the flooring to the adhesive. This causes unwanted softening of the adhesive and may lead to release of the bond.

plastisol

Made from a special kind of vinyl resin which is suspended in plasticizer and stabilizer to make it pourable as a liquid for coating purposes.

polish

A temporary coating that enhances the appearance and protects the substrate to which it is applied.

polishing

The application of a temporary coating (e.g. wax) that protects the floor from wear, abrasion, soiling and discolouration, while smoothing the surface and significantly improving gloss. Polishes are easily removed and replaced or refurbished.

polymeric poured seamless flooring

This is a resilient flooring consisting of polymeric material applied to a substrate in a liquid form alone, or in combination with mineral or plastic chips, pigments, desiccant, or fillers, which convert or solidify into a "built-up" floor covering (such as terrazzo flooring). This type of flooring other than plant manufactured terrazzo tile is not included in the NFCA Manual.

polyvinyl chloride flooring (PVC)

Refer to vinyl flooring.

porosity

The "openness" of a substrate surface. Open pours are able to absorb liquid. Concrete and wood substrates are normally porous. If there is any doubt as to the porosity of a substrate a few drops of water on the surface will indicate if it is. If the water is quickly absorbed, the surface is porous. If the water remains on the surface, the surface is nonporous.

post-consumer material

Of, or relating to products that have been used and recycled by consumers.

post-consumer recycled content

A product that contains some percentage of material reclaimed from consumer waste.

post-industrial material

Of or relating to industrial manufacturing waste; also called pre-consumer material .

post-industrial recycled content

A product that contains some percentage of manufacturing waste material that has been reclaimed from a process generating the same or a similar product. Also called pre-consumer recycle content.

pot life

(in regard to adhesives) The period of time during which an adhesive once opened or mixed (as in those requiring a catalyst) remains suitable for use before it "sets". Refer to Part A14 - Adhesives and Fastenings for information.

powdering

Partial or total disintegration of the polish film, resulting in a fine, light-coloured material.

printing

A manufacturing method in which a pattern is made on a flooring surface. The printed pattern may be protected with a wear layer of transparent or translucent vinyl plastic. Refer also to rotovinyl and rotogravure flooring.

R

radiant heated floor

A substrate that is heated by built-in heating coils, pipes, or ducts that also serve as a means to heat an area. Some types of resilient flooring may be installed over radiant-heated substrates as long as the surface temperature does not exceed 30°C (85°F). When temperatures exceed this limit, the flooring can soften and increase the risk of indentation. Some types of resilient flooring may not be installed over radiant heated substrates. In all cases refer to the flooring manufacturer for requirements.

ramp

An inclined plane connecting two different floor levels and used instead of steps. Depending on the slope, the use of a slip resistant flooring material may be required.

reducer strips / protective edgings

Purpose made rubber, vinyl, or metal mouldings used to protect / cover exposed "raw" edges of resilient flooring where it abuts another type of floor covering (e.g. carpet, hardwood, laminate, tile, or concrete flooring) and at doorways. There are two basic types: (1) applied-before, i.e., secured in place before flooring is installed with floor material fitted to them and (2) applied-after, i.e., installed on top of flooring after it has been installed.

relative humidity

The ratio of the amount of water vapour present in the air to that which the air would hold at saturation at the same temperature. It is usually considered on the basis of the weight of the vapour, but for accuracy should be considered on the basis of vapour pressures.

repeat

The distance between identical design/pattern elements in tile or sheet goods.

residential flooring

This is resilient flooring specifically designed for installation in residential settings. Refer also to commercial flooring.

resilience

The ability of a flooring to recover its original appearance and thickness after being subjected to mechanical compressive forces (e.g. furniture) or crushing under traffic (foot or wheeled loads).

resilient flooring

A non-textile floor covering material manufactured in sheet or tile form (or formed in place material not included in this NFCA manual) that is often referred to as hard-surface flooring. Such material includes but is not limited to solid and composition vinyl, rubber, linoleum, and cork flooring. The term does not necessarily define a physical property.

resilient tile flooring

Individual modular resilient flooring material (such as solid and composition vinyl, rubber, linoleum, and cork tile) usually square with sides of 200 mm (8") up to 600 mm (24") with 200 mm (8") and 300 mm (12") square tile the most common size. Tile is also available in rectangular sizes with sides of 200 (8") to 900 mm (36").

riser

The vertical or front face of a step between two stair treads.

rolling

Procedure for removing trapped air, flattening adhesive ridges, and for setting floor covering into the adhesive to achieve a uniform bond. When recommended, flooring should be rolled in one direction and then in the cross direction immediately after placing the flooring into the adhesive. Rolling should be started at the centre of sheet flooring working outward to move trapped air to the edges.

rolling loads

These are loads imposed on flooring by moving heavy fixtures, appliances, equipment, and other materials or items using dollies, carts, litters, gurneys, etc. As the bearing surface area of some of these wheels and casters is deceptively small it results in higher compressive forces than may be anticipated. This is particularly important to note in regard to newly installed flooring which should not be exposed to such rolling traffic for at least 72 hours after installation to allow the adhesive to set and dry. A minimum 6 mm (1/4") or thicker plywood, hardboard, or other hard underlayment panel may be used to prevent damage from such rolling loads.

rotogravure / rotovinyl flooring

A printed sheet vinyl flooring in which the pattern is printed on a backing by a rotogravure process. The patterned material is protected with a wear layer of transparent or translucent vinyl plastic. Also called rotogravure sheet vinyl flooring.

rubber flooring

A floor covering material manufactured in tile or sheet form, consisting of natural or synthetic rubber, or both, in combination with mineral fillers and pigments.

runners

A continuous material used as a surface covering in traffic lanes and stairs with a margin on each side.

S

scarify

This is a mechanical process (e.g., shot or bead blasting) used to roughen up a concrete surface to obtain a better bond.

scratches

Slight incisions, breaks, tears or indentations on the surface of flooring caused by abrasive friction.

scribing

An installation term for the method of transferring the exact irregularities of a wall, floor or other surface onto a piece of resilient flooring by a tracing technique. The flooring is then cut to fit exactly.

scrubbing

Washing a floor by wetting it with detergent solution, then using a moderately abrasive non-woven pad or appropriate brush, either by hand or attached to a low-speed floor machine, to vigorously agitate the wet surface. This procedure is used when a floor is heavily soiled, and less-aggressive cleaning methods have been unsuccessful. The floor should always be rinsed thoroughly after scrubbing.

scuff

A wearing away of the surface through abrasion or a thermo-mechanical displacement of the upper surface of the floor covering by friction from traffic bodies.

scuffing of flooring

A wearing away of the surface through abrasion or a thermo-mechanical displacement of the upper surface of the floor covering by friction from traffic bodies.

scuffing of polish

Disfigurement of polish film resulting from an abrading or scraping action. It is usually repairable by cleaning and recoating with polish.

sealer

Any finishing material that is applied with the primary purpose of stopping the absorption of stains or succeeding coats.

seam

(or joint) In flooring installation, the line formed by joining, without overlaps or gaps, the edges of two pieces of flooring by use of adhesive (chemically bonding) or by fusion (heat welding) using continuous filler rods and heat.

seam adhesive

A specifically formulated adhesive for chemically securing cut edges of resilient flooring material to be seamed.

seam coating

A clear coating normally used to coat the surface area of seams in residential resilient flooring. The coating protects the seam from dirt and helps to hold seams together.

seam sealing

A procedure for sealing seams using a special applicator and liquid sealant.

seam welding (heat welding)

A procedure of heat welding certain seams in certain types of floor covering.selvage edge

Material in excess of the width and/or pattern of sheet goods that is cut off before the flooring is seamed or matched at the edges.

set match

A pattern design matching straight across the sheet from edge to edge.

shading

A change in the appearance of a flooring product (e.g. tile) due to production variations.

sheen

The degree of lustre of the dried film of a finishing material (polish).

sheet flooring (resilient)

Flexible resilient flooring packaged in roll form (usually manufactured in width ranging from 1800 mm (72") up to 4575 mm (180") with rolls up to 45 m (150 ft.) long to allow "seamless installations in small rooms and to minimize seams in large rooms.

shelf life

The period of time that the manufacturer guarantees unopened adhesive will be useable. The date of manufacture is normally stamped on the adhesive container. In most cases, the adhesive will be usable for a period of time following the shelf life. When the adhesive becomes unusable, the handling characteristics are affected.

side seams

Seams running the length of the flooring. Sometimes called length seams.

slip resistant flooring

Resilient flooring having a minimum having a static coefficient of friction value of no less than 0.50.

solid vinyl (homogeneous)

A resilient floor covering in sheet or tile form composed of binders, fillers, pigments, and stabilizers, thoroughly blended and subjected to heat and pressure to form a completely homogeneous material.

sound transmission class (STC) rating

This is the rating of airborne sound transmission. Most resilient flooring (except for flooring with a bonded acoustical or cushion backing) has little or no effect in regard to sound reduction and will not dampen reverberant or airborne sound. Refer to A08C - Acoustical Issues.

specialty flooring (resilient)

Resilient flooring that is required to meet a specific requirement such as slip resistance, static control, sound reduction, or a function such as sporting activities.

spray-buffing

The application and buffing of a dilute floor polish or a specially formulated spray-buffing compound. This procedure is especially useful in high-traffic areas. The liquid is sprayed on the floor and then immediately buffed with a floor machine until dry. This procedure helps to reduce the need for stripping by protecting the base coat of polish. To prevent pad or brush contact with the flooring material, spray buff only on clean floors with sufficient (three to five coats) polish.

spread rate

The amount of coverage that can be expected from a given amount of adhesive when spread using the recommended trowel.

stain and reagent resistance

Some flooring types such as linoleum are generally resistant to dilute acids, oils, greases and most common organic solvents. Some types are susceptible to damage from prolonged exposure to alkalis (bases). Vinyl flooring is generally resistant to alkalis, acids, alcohols, oils, greases and aliphatic hydrocarbons but can be softened by ketones, esters and chlorinated and aromatic hydrocarbons. If any particular chemicals or substances are going to be present in the environment, adequate testing should be performed on the floor covering material in advance to ensure suitability for such applications. On floors where polish is recommended, tests should be made on polished samples. High quality commercial floor polish will provide a good barrier to most stains and reagents.

stair nosing

Material used to cover the nose of a stair and demarcate the edge. The material may be part of the stair tread or be a separate piece or material.

static dissipative flooring

A type of static-control flooring used extensively in the electronics industry to prevent damage to sensitive components. Refer also to Part B04C – Material Guide (resilient flooring) for additional information.

static load indentation resistance

The ability of flooring to resist or bounce back from high load, small indenture exposure from such things as hospital beds, table and chair legs, stiletto heels, etc. Static load indentation resistance is most dependent on the product construction, presence and type of backing, surface embossing and pattern (which may help to mask indentation).

static loads

These are any loads remaining in a stationary position for long periods of time. Flooring manufacturers establish static load limit values to aid in the selection and protection of resilient flooring for use under these conditions.

step return

A term for that part of a staircase tread that extends over the riser. Also known as a bull nose or extended nosing.

stiffness

Resistance of material, such as resilient flooring, to bending.

stringer or skirting material

A strip of flooring material installed on the sides of stairs.

stripping

This is the removal of old floor polish, using a strong, and usually very alkaline, detergent and scrubbing procedures. Stripping is done to small segments of the floor at a time, with each segment being thoroughly rinsed before moving to the next segment. Stripping (and necessary reapplication of polish) is a very aggressive floor maintenance procedure and should be done only when absolutely necessary.

subfloor / substrate

The floor surface to which flooring materials are applied/installed. Refer also to underlayment.

suspended floor

A sub-floor constructed over a minimum of 450 mm (18") of cross-ventilated air space.

T

telegraphing

This is a condition where substrate irregularities, imperfections, or patterns are visibly transmitted through the flooring.

template

A paper or cardboard pattern used by installers as a guide for cutting resilient flooring for areas having complicated or unusual shapes.

threshold

The raised material beneath a door, also known as a door sill or saddle.

tile flooring (resilient)

Resilient flooring of various sizes (usually square) packaged in flat pieces and installed individually.

traffic

The passing back and forth of persons over a given flooring surface area.

traffic staining / yellowing

Yellowing caused by a chemical interaction of the anti-oxidants put in rubber shoe soles and plasticizers in vinyl. The more plasticizer, usually the higher the staining, except with the use of very expensive non-staining plasticizers.

traffic wear and durability

The durability of flooring related to traffic wear due to many factors such as abrasion resistance; resistance to gouging, punctures, cuts and impacts; rolling and sliding (dynamic) loads; and standing (static) loads.

transition strip

Normally a metal, vinyl, or rubber strip that provides a smooth transition from a higher piece of flooring to a lower piece, such as resilient flooring to carpet.

tread

The horizontal (walking surface) part of a stair or step. Floor covering materials used for covering stair treads.

trim

These are floor "finishing" materials such as baseboard, transition trims, etc.

trowel

Hand implement used for spreading adhesive on substrate surfaces. Trowels are generally notched with a pattern and notch size to suit resilient flooring backing and adhesive requirements.

TSP

Tri-sodium Phosphate commonly used to remove surface contaminates from flooring. Use of this material should be clarified with the flooring manufacturer before using.tunnelling

When incomplete bonding causes releasing from the substrate and long areas of the flooring form tunnel-like deformities, usually over underlayment joints. Tunnels are normally caused by movement of the underlayment joints from moisture growth and are sometimes combined with product growth.

two-tone

A pattern of two shades of the same colour.

U undercutting

A procedure that removes an appropriate amount of trim around doors to allow flooring material to pass freely underneath.

underlayment

A suitable separate layer of material generally installed over a substrate or subfloor to provide a smooth level surface that is acceptable for the installation of resilient floor coverings. Refer also to subfloor / substrate.

vinyl asbestos tile

An obsolete form of resilient tile composed of vinyl plastic binders, chrysotile (VAT) asbestos fibres, mineral fillers, and pigments.

vinyl backed

Resilient flooring with a laminated open or closed cell foam backing.

vinyl composition tile (VCT)

A thoroughly blended composition of vinyl resins, plasticizers, inert fillers, pigments, and stabilizers formed under pressure and heat into sheet form, and then cut into tile size.

vinyl flooring

A resilient or flexible floor covering material that, apart from an integral backing, consists of a mixture of polyvinylchloride resin(s), plasticizers, stabilizers (and other additives), and possibly opacifying agents and fillers. Vinyl flooring may be heterogeneous or homogeneous.

vinyl resin

Polyvinyl chloride (PVC) which has been polymerized from vinyl chloride monomer into a powdery form for mixing with other ingredients to form rigid vinyl (as found in house siding, PVC pipe, credit cards, etc.) or plasticized vinyl (as found in shower curtains, pool liners, and vinyl flooring).

VOC

Abbreviation for volatile organic compound.

W

wax (finish) A temporary coating / finish sealer (typically applied on linoleum) that is normally burnished to enhance wear and appearance. This type of finish water spots and stains easily, but is simple to repair.

walk-off mats

Mats located at entryways to collect dampness, dirt and other materials before they are tracked into the building and onto resilient flooring.

wear

This is the deterioration of flooring due to the accumulation of abrasion, gouging, scratching, and scuffing.

wear layer

The surface or wear layer portion of a resilient floor covering that protects the pattern and/or textured finish. Exceptions are flooring materials made entirely of one component or layer, or in multiple layers.

working time

When installing sheet flooring, this is the amount of time allowable from the laying in of the flooring until all cutting and fitting must be completed. When installing tile, this is the amount of time from the point when the adhesive is dry to the touch until the tile will no longer bond. Temperature, humidity, and porosity of the subfloor affect working time.

patching

Process of repairing holes, cracks, breaches, etc. in a floor substrate prior to installation of resilient flooring.

pattern matching

A procedure for ensuring correct alignment of patterned materials.

pH

A value representing the concentration of hydrogen ions in gram equivalents per litre used to indicate the acidity or alkalinity of a substance on a scale from 0 to 14 with 7 representing neutrality, numbers less than 7 increasing acidity, and numbers greater than 7 increasing alkalinity. Laboratory and field testing for pH must be done with distilled water.

- alkali: (or Base) any substance which when dissolved in water yields a pH above 7.

- acid: any substance which when dissolved in water yields a pH below 7.

- buffer: chemical agents that are used to maintain a constant pH level.

Special oils developed to impart flexibility and special properties like stain resistance to plastics, like PVC; they are added in the compounding step to the vinyl resin. The most common plasticizer used in vinyl is dioctyl phthalate (pronounced "die-octil-thal-ate") or DOP.

plasticizer migration