AA4 - FLOOR FLATNESS AND LEVELNESS

Preface:

The following appendix is a discussion on floor flatness measurement methods and is provided for general information only.

.01 HISTORY OF FLATNESS AND LEVELNESS MEASUREMENT OF CONCRETE SUBSTRATE SURFACES TO RECEIVE FLOORING

.02 THE F-NUMBER SYSTEM

.04 WAVINESS INDEX

.05 COMPUTER-SIMULATED 10-FOOT STRAIGHTEDGE

.06 COMPARISON OF MEASUREMENT SYSTEM TOLERANCES

The following appendix is a discussion on floor flatness measurement methods and is provided for general information only.

.01 HISTORY OF FLATNESS AND LEVELNESS MEASUREMENT OF CONCRETE SUBSTRATE SURFACES TO RECEIVE FLOORING

- For over 50 years, concrete floor surface tolerances were typically measured and described by the maximum gap allowed under a 3000 mm (10 foot) long straightedge placed anywhere on the floor surface. This manual method was difficult, especially for large areas, and often results were deceptive, too stringent, and not reproducible. Clearly, a better measurement technique was needed.

- During the 1970's and 1980's, sophisticated instruments were developed to measure floor flatness, particularly in response to the need for producing super-flat floors in high storage rack, narrow aisle warehouses to control the sway of moving forklifts. There are two accepted measurement methods being used today, each established by the American Society for Testing and Materials (ASTM). One is described in ASTM E1155, "Standard Test Method for Determining FF Floor Flatness and FL Floor Levelness Numbers", while the other is described in ASTM E1486, "Standard Test Method for Determining Floor Tolerance Using Waviness, Wheel Path, and Levelness Criteria".

.02 THE F-NUMBER SYSTEM

- The American Concrete Institute (ACI) recommends that flatness and levelness be described using the F-Number System as outlined in ACI 302.1R-96, "Guide for Concrete Floor and Slab Construction" and ACI 117R-90, "Standard Tolerances for Concrete". This system identifies two numbers: FF (floor flatness) controls local surface bumpiness (or waviness) by limiting the magnitude of successive 300 mm (1-foot) slope changes. The other, FL (floor levelness) controls overall levelness by limiting differences in the average over 3000 mm (10-foot) elevations along sample measurement lines.

- ACI 117R-90 (Commentary) states: "None of the conventional concrete placement techniques in use today can adequately compensate for form or structure deflections that occur during the concrete placement and, for this reason, it is inappropriate to specify levelness tolerances on unshored floor construction." For concrete slabs receiving resilient floor covering, therefore, it is most important to describe limits of floor flatness. In practice, FF and FL values generally fall between 12 and 45. The scale is linear, so that relative flatness / levelness of two different floors will be in proportion to the ratio of their F-numbers. For example, an FF 30 / FL 24 floor is exactly twice as flat and twice as level as an FF 15 / FL 12 floor.

- ACI 302.1R-96 gives F-number results that can be achieved by following various slab construction procedures. It recommends that slabs to receive thin set flooring with moderate or heavy traffic have composite flatness and levelness of FF 35 / FL 25. However, it also advises that the selection of the proper FF / FL tolerances for a new project is best made by measurement of a similar satisfactory existing floor.

- The "Evaluations" Part of the USA MASTERSPEC® Guide Specification Section 03300, Cast-In-Place Concrete, has a guide to floor flatness and levelness tolerances for various floor use categories. It recommends a minimum FF 20 / FL 17 for sub-floors receiving thin coverings that will not mask the sub-floor condition. (Some industry sources suggest these limits are too low because sub-floor ripples begin to telegraph through highly reflective coverings when FF is in the mid-20's range).

- SPECTEXT® Guide Spec Section 03346, Concrete Floor Finishing, includes "Appropriate Options for Slabs Under Various Floor Finishes". It recommends a minimum FF 75 / FL 50 under glossy resilient finishes, and a maximum variation using a straightedge of 3 to 6 mm (1/8" to 1/4") under seamless resilient flooring. (These F-numbers are much higher than other industry guidelines and may be too expensive to accomplish and unnecessary where thin floor coverings are to be applied.)

- At a World of Concrete seminar in 1992, it was proposed that slabs on grade where vinyl tile is used in places such as public areas of shopping centres and hospitals should have a specified overall value of FF 36 / FL 20 and a minimum local value of FF 24 / FL 15.3. (Experience shows that these values are appropriate where resilient floor coverings are employed.)

.04 WAVINESS INDEX

- Another more recent measurement method is described in ASTM E 1486. This method was developed primarily to measure floor surface wavelengths from 600 to 3000 mm (2 to 10 feet) --- those that most affect forklift ride ability at typical speeds on floors designed for random vehicular traffic. Proponents of this method have submitted proposed guidelines to ACI Committee 117 suggesting tolerance standards. These guidelines include the recommendation that concrete floors with vinyl tile covering be specified with a Surface Waviness Index (SW12-10) of 0.12 inches. This is approximately equivalent in the tested area to FF 28 / FL 20 and to a 6 mm (1/4") gap permitted under a 3000 mm (10-foot) straightedge.

.05 COMPUTER-SIMULATED 10-FOOT STRAIGHTEDGE

- The F-number and Waviness Index Systems were developed in part to remedy the lack of an ASTM test method and other perceived difficulties with the traditional 3000 mm (10-foot) straightedge method. Now, however, with computer software, the data used to compute F-numbers and Waviness Indices can also be used to compute deviations from a 3000 mm (10-foot) straightedge.

- Computer-simulated straightedge analysis resolves the shortcomings of actual straightedge measuring. Random placement of the straightedge is replaced by the same adherence to data collection rules used for FF / FL (ASTM E 1155) and for W12-10 (ASTM E 1486). Thus, technicians are freed from the awkward and time-consuming task of shimming the straightedge and rolling bars underneath.

.06 COMPARISON OF MEASUREMENT SYSTEM TOLERANCES

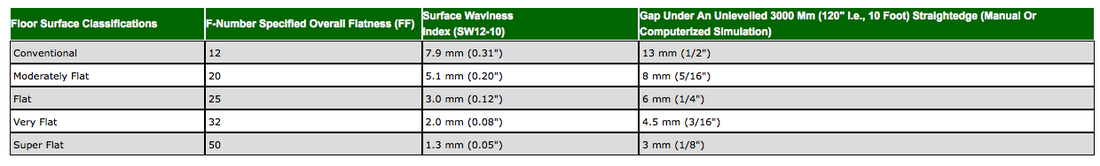

- While there is no direct equivalent between F-numbers, Waviness Index and straightedge tolerances, the proposed revision at ACI 117R-90 suggests a rough correlation between the three systems.

.07 REMEDIAL MEASURES

.08 LIMITATION OF MEASUREMENT METHODS

.09 FOOTNOTES:

NOTE: This Part is from a previously printed article from Armstrong World Industries.

- While there is no direct equivalent between F-numbers, Waviness Index and straightedge tolerances, the proposed revision at ACI 117R-90 suggests a rough correlation between the three systems.

- ACI 302.1R-96 identifies precautions, influencing factors, construction environment, and measurement timeliness relative to maintaining flatness and levelness tolerances. It suggests: Remedial measures for slabs on ground might include grinding, planing, surface repair, retopping, or removal and replacement. For suspended slabs, remedial measures are generally limited to grinding or use of an underlayment or topping material. Contract documents should clearly identify the acceptable corrective method(s) to be used.

- NFCA requires that where concrete level tolerances indicated in Part A10 - Acceptable Conditions, item 3.06.6 are not provided that corrective measures indicated in item 3.07 are instituted. Refer also to Part A13 - Patching and Filling for recommended patching / levelling compounds and for General Contractor and Flooring Contractor responsibilities.

.08 LIMITATION OF MEASUREMENT METHODS

- One important reason for specifying flatness tolerance for concrete slabs to receive resilient flooring is to attempt to minimize tile "runoff" and gapping due to slab surface waviness. F-numbers and Waviness Index numbers necessary to accomplish this have not been determined. However, experience shows that floors with a maximum 4.5 mm (3/16") gap under an unlevelled 3000 mm (10-foot) straightedge tend to lessen the tendency for tile runoff.

- Thin resilient flooring and resilient flooring without a cushion / felt backing can exhibit show-through of very small sub-floor irregularities and roughness. Methods that indicate surface flatness by measuring elevations at 300 mm (12") or more increments cannot reflect surface imperfections that occur at smaller intervals. Only visual inspection will show surface defects such as concrete trowel marks, small protrusions, or pits. Resilient flooring finishing techniques and products that give increased glossiness will accentuate the telegraphing of such sub-floor unevenness or texture. Therefore, specifications for slabs to receive resilient flooring should address the issue of small-scale smoothness, even if only from a qualitative point of view.

.09 FOOTNOTES:

- "Commentary on Standard Specifications for Tolerances for Concrete Construction and Materials (ACI 117-90)", ACI 117R-90, American Concrete Institute (ACI), Detroit, p.7.

- "Guide for Concrete Floor and Slab Construction", ACI 302.1R-96, American Concrete Institute (ACI), Detroit, p. 45.

- Tipping, Eldon, "Bidding and Building to F-Number Floor Specs", Concrete Construction, January 1992, p. 19.

- Ytterberg, Carl N., "The Waviness Index Compared with Other Floor Tolerancing Systems - Part 1", Concrete International, October 1994, p. 69.

NOTE: This Part is from a previously printed article from Armstrong World Industries.